Packaged STP plants are changing the game in wastewater management through their compact, self-contained design and high treatment efficiency. These pre-manufactured units provide a vital solution to treat sewage on-site in residential, commercial, and small industrial properties. These systems blend physical, biological, and chemical processes to remove contaminants from wastewater and make it safe for discharge or reuse.

The sewage treatment process works in three main stages: primary, secondary, and tertiary treatment. Wastewater goes through screening, settling, biological treatment, and advanced filtration to make the water clean enough for recycling. Packaged STPs excel because they adapt well to different sewage loads and leave a smaller environmental footprint than traditional systems. A packaged sewage treatment plant does more than meet regulations—it’s a smart infrastructure choice that enables water reuse and reduces environmental impact.

This piece takes you through the complete design of packaged STP plants from inlet to clean water output. You’ll learn about core components and follow the treatment process step by step. We also cover installation guidelines and troubleshooting tips. The guide shows how innovations like SUSBIO ECOTREAT are setting new standards in packaged STP design.

Core Components of a Packaged STP Plant

A packaged STP plant works best when all its critical components work together. These components turn raw sewage into clean, usable water through a series of treatment steps that improve water quality.

Inlet Chamber and Screening Unit

Raw sewage enters the STP plant through the inlet chamber. This reception area removes large debris that could damage equipment downstream. The screening unit uses bar screens to filter out items like plastic bottles, rags, and sticks. This first step keeps wastewater flowing smoothly and protects pumps and mechanical parts from damage.

Primary Settling Tank for Solid Separation

The wastewater moves from screening to the primary settling tank or primary clarifier. The water slows down here, letting heavy solids sink to the bottom. This tank removes 50-70% of suspended solids and 30-40% of BOD (Biochemical Oxygen Demand). This is a big deal as it means that the next biological processes have less work to do. The tank comes in rectangular or circular designs with special zones that spread water evenly and reduce turbulence. The outlet zones have weirs that help maintain uniform water flow.

Aeration Chamber with Diffused Air System

The aeration chamber is where the real biological treatment happens. This tank introduces air to feed aerobic microorganisms that break down organic pollutants. Blowers and diffusers at the tank’s bottom create fine air bubbles that rise slowly through the wastewater. This setup spreads oxygen evenly, transfers it efficiently, and saves energy. Fine bubble diffusers work with half the airflow of coarse bubble systems, which cuts operating costs over time.

Secondary Clarifier for Biomass Separation

The secondary clarifier receives water after biological treatment. It separates the biological floc (activated sludge) from treated water. These tanks are deeper than primary clarifiers to give fine particles more time to settle. They remove 85-95% of remaining solids, producing clear water ready for disinfection. Some settled sludge goes back to the aeration tank to keep microbe levels right, while excess sludge moves on for more treatment.

Disinfection Unit: UV vs Chlorination

Disinfection kills pathogens before water discharge. UV disinfection and chlorination are the main methods used. UV systems use special light wavelengths to damage bacteria’s DNA in seconds, while chlorine takes 30+ minutes. Chlorination has been used widely but creates potentially harmful byproducts and needs careful chemical handling. Plants choose between these based on their tank size, budget, and specific needs.

Sludge Handling and Dewatering System

The sludge handling system deals with waste generated during treatment. Modern packaged STPs use thickening systems to concentrate solids, then dewater them using belt filter presses, centrifuges, or screw presses. This removes water and makes the sludge easier and cheaper to transport. Good sludge management keeps plants environmentally compliant and helps avoid contamination and penalties.

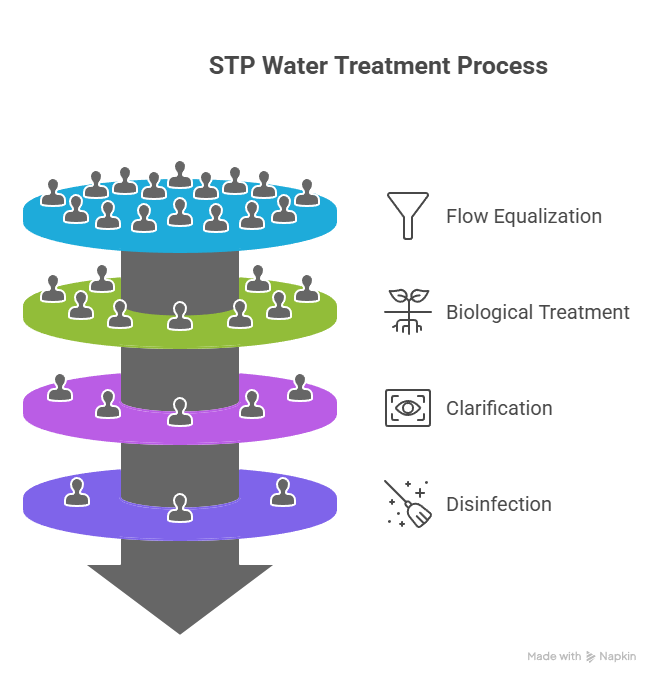

Step-by-Step STP Water Treatment Process

The experience of converting raw sewage into clean water in a packaged STP plant needs several carefully coordinated processes. Each treatment stage builds on the previous one to change wastewater into environmentally safe effluent.

Raw Sewage Entry and Flow Equalization

The treatment cycle starts as raw sewage enters the STP plant through an inlet chamber that measures the original flow. The system immediately removes large objects through screening to protect downstream equipment from damage. The screened wastewater then moves to the equalization tank, which serves as a vital buffer in the treatment process.

Flow equalization tackles a big challenge in wastewater treatment – daily changes in sewage volume. The equalization tank stores extra sewage during peak hours and releases it at a controlled rate when flow is low. This regulation helps downstream processes receive steady flow and improves treatment efficiency. The system forces compressed air into the tank to keep solids suspended and prevent septicity, which reduces odor formation.

Biological Treatment Using Aerobic Bacteria

The wastewater moves to biological treatment after equalization – you could call it the heart of the STP process. Aerobic microorganisms break down dissolved organic matter using oxygen supplied through diffusers or mechanical aeration devices. These oxygen-dependent bacteria eat organic pollutants and convert them into carbon dioxide, water, and biomass.

The activated sludge process creates an environment where microorganisms form biological flocs that absorb and metabolize organic contaminants. This biological degradation completes in hours what takes years in lakes or rivers. The process works especially well when wastewater has BOD levels below 2,000 ppm, and removes up to 90% of organic pollutants.

Clarification and Sludge Recirculation

The mixture enters secondary clarifiers after biological treatment. Here, biological flocs separate from treated water through gravity settling. The clarified water flows to later treatment stages, while the settled biomass serves two purposes: some returns to aeration tanks to maintain microbial population, and excess sludge goes through more processing.

The recirculation system plays a key role in treatment efficiency by maintaining steady microorganism concentrations in biological treatment. Returning activated sludge speeds up incoming wastewater treatment because it provides a 3-year-old microbial community that already knows how to break down specific pollutants.

Final Disinfection and Effluent Discharge

The last vital step involves disinfection to eliminate remaining pathogens. This final treatment stage uses either chlorination or ultraviolet (UV) radiation. UV disinfection has become more popular than traditional chlorination because it kills pathogens without creating potentially harmful byproducts.

During UV disinfection, wastewater moves through chambers where UV light damages microorganisms’ DNA to prevent reproduction. Chlorination adds chlorine compounds to wastewater, which effectively kills pathogens but needs careful monitoring to avoid chemical residues in the final effluent.

The treated water meets regulatory standards and either flows into water bodies or gets repurposed for non-potable applications. This completes its transformation from waste to valuable resource.

Installation and Operational Guidelines

The success of any STP plant depends on how well you install and run it. A technically sound system needs more than just the right parts – it needs proper setup to work in ground conditions.

Site Preparation and Civil Work Requirements

You must assess the site before starting any installation. A geotechnical survey will give a clear picture of soil strength, groundwater levels, and drainage patterns. The foundation of packaged STP units needs careful thought about bearing capacity and water table changes. This prevents tanks from floating up or moving. Some areas with high groundwater pressure might need anti-flotation slabs.

The plant’s location needs smart planning. Keep it at least 7 meters away from living spaces, preferably where the ground slopes away from buildings. On top of that, desludging vehicles need easy access. Hard standing areas should be within 30 meters of the plant. Dig deep enough to fit both incoming wastewater pipes and discharge points. Make sure you have a plan to dispose of the dug-up materials.

Electrical and Plumbing Integration

The STP’s power supply must follow electrical rules and get certified by qualified electricians. Protect cable routes well and place service boxes in the right spots. All pipes should handle speeds between 0.6-2.5 m/s. Set up unit bypasses that use gravity through outfall conduits or terminal tanks before the final outfall.

The design and construction phases need teamwork between electrical, plumbing, and sanitary systems to avoid clashes. Good venting is a must – place it downwind from occupied buildings to keep odors away.

Start-up Commissioning Checklist

Take these key steps before commissioning:

Run hydrostatic tests, check for leaks, and calibrate instruments

Commission in phases (25%, 50%, then full load)

Keep track of operational data during each phase to fine-tune

Check electrical connections, pump function, and control systems

Test all mechanical equipment with proper run-in time

Your commissioning documents should include pre-commissioning reports, site assessments, and complete handover papers.

Routine Maintenance and Inspection Schedule

Regular upkeep helps the system run better, last longer, and avoid problems. Use a detailed checklist each month to check tanks, fasteners, and metal parts. Clean tanks every 6-12 months with non-corrosive cleaning agents.

Check pumps and control systems every three months. Look at electrical connections and listen for odd noises. Keep detailed logs of all work done, unusual findings, and water quality readings. Fix things before they break – waiting for equipment failure will get pricey and cause more downtime.

Daily checks of aeration patterns and pump sounds can catch problems early and save money on repairs.

Troubleshooting and Performance Optimization

STP plants need constant monitoring and quick troubleshooting to work at their best. Even the best-designed systems face problems that you need to fix quickly to keep things running smoothly.

High TSS in Effluent: Causes and Fixes

High Total Suspended Solids (TSS) in effluent shows your treatment isn’t working well. You’ll see this happening because of several reasons. A visible sludge blanket in your aeration or clarifier chambers is a clear sign something’s wrong. The problem usually stems from poor air pumping, uneven tanks, broken aerators/blowers, or cracked air lines. TSS levels in lagoon systems can be higher in the effluent than the influent because of algae cells, bacterial floc, and sludge particles.

You can solve high TSS problems by ensuring proper mixing and aeration throughout your system. Good turbulent mixing stops thermal stratification that causes short-circuiting and raw sewage solids in effluent. If you have too much sludge, check the blanket thickness with a survey before you clean it out partially or completely.

Odor Issues from Aeration Tank

Bad smells usually mean your STP plant has anaerobic conditions. Not enough aeration is often the biggest problem. This releases hydrogen sulfide gas that smells like rotten eggs. Too much sludge can also create methane and ammonia. Chemical imbalances might kill good bacteria too.

The fix involves upgrading to energy-efficient blowers with fine-bubble diffusers and regular equipment maintenance. More oxygen helps aerobic bacteria digest organic matter better, which stops those smelly anaerobic conditions.

Foaming in Biological Chambers

STP plants face three types of foaming issues. Biological foaming happens when too many filamentous bacteria make extracellular polymers. Non-biological foaming comes from surfactants like detergents that reduce water surface tension. Too much organic loading or unbalanced nutrients create foam through EPS production.

You can tackle filamentous foaming by chlorinating the return activated sludge line early. Use 3-4 ppm per 1,000 ppm total volatile suspended solids. Anti-foaming agents help with surfactant foam temporarily, but you must find and fix the source.

Energy Consumption Monitoring Tips

Complete energy audits help find waste in STP plants. Your aeration systems use most of the energy, so focus there first. Variable speed drives on pumps and blowers can adjust motor speeds based on actual needs, which saves lots of energy.

You can capture excess heat from processes like anaerobic digestion to dry sludge or heat spaces. Keep pumping systems between 0.6-2.5 m/s velocity ranges to work best. Immediate monitoring systems let operators adjust processes based on energy patterns, which can cut energy use by 15-20%.

SUSBIO ECOTREAT: A Benchmark in Packaged STP Design

SUSBIO ECOTREAT stands out as a remarkable state-of-the-art solution among modern packaged STP systems. This advanced wastewater treatment technology brings a major breakthrough in environmentally responsible sewage management.

Dual Treatment Process: Anaerobic + Aerobic

SUSBIO ECOTREAT’s powerful dual biological treatment approach combines anaerobic and aerobic processes. The original phase breaks down complex organic compounds. The aerobic treatment then completes the purification process. This complete method removes pollutants better than single-process systems. The system effectively reduces BOD, suspended particles, nitrogen, and phosphorus.

FRP Modular Construction for Durability

The system’s high-quality fiber-reinforced plastic (FRP) construction provides excellent protection against environmental factors and chemicals. The lightweight composite material lasts 15-25 years, unlike traditional concrete structures. FRP’s smooth surface prevents contaminant buildup and makes maintenance and cleaning easier.

90% Energy Savings with Smart Automation

SUSBIO ECOTREAT uses up to 90% less electricity than conventional STPs. Optimized aeration systems and energy-efficient components create this remarkable efficiency. The control systems monitor and adjust treatment processes with up-to-the-minute data. This automation eliminates the need for constant human supervision, making it perfect for unmanned or remote locations.

Plug-and-Play Installation Model

SUSBIO ECOTREAT comes as a prefabricated, ready-to-install unit, unlike traditional plants that take months to build. The installation takes just days, which reduces site disruption and labor costs. This adaptable design works well for buildings of all types—from residential complexes to commercial buildings and industrial facilities.

Noiseless Operation for Urban Settings

The system runs quietly, making it perfect for residential and urban areas. Its advanced engineering ensures odor-free operation. This solves a common issue with regular sewage treatment plants that create disruptive noise from mechanical equipment, water flow turbulence, and ventilation systems.

Conclusion

Packaged STP plants are without doubt a major step forward in wastewater treatment technology. This article shows how these compact, self-contained systems turn raw sewage into clean, usable water through several treatment stages. Every part of the system plays a key role in the treatment chain – from inlet chambers and screening units to disinfection systems.

The treatment process works remarkably well. Raw sewage enters and goes through flow equalization first. Next comes biological treatment with aerobic bacteria, followed by clarification with sludge recirculation. The final step is disinfection before discharge. This step-by-step method removes contaminants thoroughly while meeting environmental regulations.

Your packaged STP plant needs proper installation and regular maintenance to work well. The system’s lifespan and performance depend on good site preparation, proper electrical and plumbing setup, careful commissioning, and scheduled maintenance. These basic requirements often get overlooked but will give you the results you want on the ground.

Problems will come up, so it helps to know about common issues like high TSS in effluent, odd smells, and foaming. This knowledge lets facility managers fix things quickly. Keeping an eye on energy use can also help cut costs while keeping the treatment working well.

The SUSBIO ECOTREAT system shows how state-of-the-art technology keeps pushing packaged STP technology forward. It works great in homes, businesses, and factories thanks to its dual treatment process, tough FRP construction, energy savings, and quiet operation.

The rise of packaged STP plants shows we’re more committed to eco-friendly water management. These systems handle current wastewater needs and help the environment by reusing water and cutting pollution. Water shortages are becoming more common worldwide, so packaged STPs will become even more vital to our water management setup.

Modern packaged STP plants are compact and modular, making them perfect for new buildings and modernizing old ones. They handle different sewage loads well and have less environmental impact than traditional systems, which makes them the better choice for many uses.

Packaged STP technology has a bright future. Manufacturers keep making their designs more efficient, with lower energy use and better automation. These improvements will make packaged STPs even more essential for building sustainable infrastructure in communities everywhere.

Key Takeaways

Packaged STP plants offer a comprehensive solution for transforming raw sewage into clean, reusable water through integrated physical, biological, and chemical treatment processes in compact, self-contained units.

• Multi-stage treatment ensures 85-95% contaminant removal through screening, primary settling, biological aeration, secondary clarification, and final disinfection processes.

• Proper installation and maintenance are critical – site preparation, electrical integration, phased commissioning, and routine inspections determine long-term system performance and efficiency.

• Energy optimization can reduce operational costs by 15-20% through variable speed drives, fine-bubble diffusers, and real-time monitoring systems for pumps and aeration equipment.

• Modern innovations like SUSBIO ECOTREAT achieve 90% energy savings with dual anaerobic-aerobic treatment, FRP construction, plug-and-play installation, and silent operation for urban settings.

• Common issues like high TSS, odors, and foaming require immediate attention – proper aeration, sludge management, and equipment maintenance prevent costly repairs and ensure regulatory compliance.

The key to successful packaged STP implementation lies in understanding that these systems are not just equipment purchases, but integrated infrastructure solutions requiring proper planning, installation expertise, and ongoing operational commitment to deliver sustainable wastewater treatment results.

Frequently Asked Questions

Q1. What is the purpose of the inlet chamber in a packaged STP plant?

The inlet chamber serves as the entry point for raw sewage, where large debris is removed through screening to protect downstream equipment and ensure smooth flow into subsequent treatment stages.

Q2. How clean is the water produced by a packaged STP plant?

While not potable, the water discharged from a packaged STP plant is generally very clean with only slight coloration due to suspended solids. It meets regulatory standards for safe discharge or non-potable reuse applications.

Q3. What are the key components of a packaged STP plant?

A typical packaged STP plant includes an inlet chamber, screening unit, primary settling tank, aeration chamber, secondary clarifier, disinfection unit, and sludge handling system. Each component plays a specific role in the treatment process.

Q4. How can the energy efficiency of a packaged STP plant be improved?

Energy efficiency can be enhanced by installing variable speed drives for pumps and blowers, using fine-bubble diffusers in aeration systems, implementing real-time monitoring, and considering heat recovery systems. These measures can potentially reduce energy consumption by 15-20%.

Q5. What are some common issues in packaged STP plants and how can they be addressed?

Common issues include high TSS in effluent, odor problems, and foaming in biological chambers. These can be addressed by ensuring proper aeration, maintaining equipment regularly, managing sludge levels, and addressing chemical imbalances. Prompt attention to these issues is crucial for maintaining system efficiency and regulatory compliance.