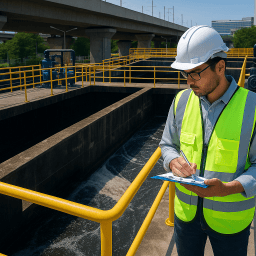

Effective wastewater treatment is crucial for maintaining environmental sustainability and regulatory compliance. A Sewage Treatment Plant (STP plant) plays a vital role treating sewage and making the water safe for discharge or reuse. Among various STP technologies, the Packaged FRP STP (Fiber-Reinforced Plastic STP) is gaining popularity due to its efficiency, durability, and cost-effectiveness. In this blog, we explore why a packaged FRP STP is the best choice for wastewater treatment.

What is an STP Plant?

An STP plant is a wastewater treatment system that removes contaminants, organic matter, and harmful bacteria from sewage, making the treated water safe for disposal or reuse. STPs are essential for residential complexes, commercial buildings, industrial units, and institutional facilities to ensure compliance with environmental regulations and sustainable water management.

Understanding Packaged FRP STP

A Packaged FRP STP is a pre-engineered, factory-made sewage treatment system constructed using Fiber-Reinforced Plastic (FRP). It is designed to provide an efficient and hassle-free solution for wastewater treatment in areas with space constraints or limited infrastructure.

Key Features of Packaged FRP STP

Compact & Space-Saving: Ideal for installation in residential, commercial, and industrial setups.

Corrosion-Resistant & Durable: FRP construction ensures longevity and resistance to harsh environmental conditions.

Energy-Efficient Treatment: Utilizes advanced treatment technologies like MBBR, MBR, and SBR to reduce energy consumption.

Quick & Easy Installation: Factory-built units enable quick installation with minimal civil work.

Low Maintenance: Requires minimal operational oversight, reducing long-term maintenance costs.

Eco-Friendly & Compliant: Meets pollution control board norms and promotes water recycling.

Eco-Friendly & Sustainable: Uses advanced biological treatment processes for high efficiency.

High Durability with FRP Construction: Corrosion-resistant and long-lasting.

Low Maintenance & Operational Costs: Designed for ease of use with minimal maintenance.

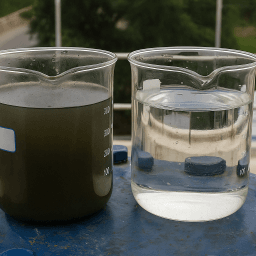

Superior Water Quality Output: Ensures treated water is safe for reuse.

Advantages of Choosing a Packaged FRP STP

1. High Treatment Efficiency

Packaged FRP STPs use Moving Bed Biofilm Reactor (MBBR), Membrane Bioreactor (MBR), and Sequential Batch Reactor (SBR) technologies to ensure efficient removal of organic pollutants, suspended solids, and harmful microorganisms.

2. Ideal for Space-Constrained Areas

Unlike traditional STPs that require large areas for installation, FRP STPs have a compact and modular design, making them suitable for high-density urban spaces, apartment complexes, and commercial buildings.

3. Durability and Corrosion Resistance

FRP material is non-corrosive, chemical-resistant, and weatherproof, ensuring a long lifespan and reducing the need for frequent maintenance or replacements.

4. Low Operational Costs

With automated operations and minimal human intervention, Packaged FRP STPs significantly reduce operational expenses, making them a cost-effective choice in the long run.

5. Regulatory Compliance and Environmental Sustainability

A Packaged STP plant ensures treated wastewater meets the pollution control board’s discharge norms, preventing water pollution and enabling water reuse for landscaping, flushing, or cooling tower applications.

Applications of Packaged FRP STP

- Residential Societies and Apartment Complexes

- Hotels, Resorts and Commercial Buildings

- Educational Institutions and Hospitals

- Industrial Units and Factories

- Shopping Malls and Office Complexes

Why Choose an Advanced FRP Packaged STP Plant?

With growing concerns about wastewater treatment and reuse, investing in a high-quality packaged FRP STP is a smart choice. The lightweight, durable, and easy-to-maintain design makes it the most practical solution for urban and industrial sewage management.

FAQs

1. What is the difference between a packaged STP plant and a conventional STP plant?

Packaged STP plants are pre-engineered, compact, and require minimal civil work, while conventional STPs are built on-site and take longer to install.

2. How long does a packaged FRP STP last?

Due to its corrosion-resistant FRP construction, a packaged STP can last 20+ years with proper maintenance.

3. Is a packaged FRP STP suitable for industries?

Yes, advanced FRP STPs are ideal for industrial applications where wastewater treatment is necessary before disposal or reuse.

4. Does an FRP STP require frequent maintenance?

No, FRP STPs are low-maintenance and require only periodic checks for sludge removal and system efficiency.

5. Can treated water from an STP be reused? Yes, treated water can be reused for gardening, flushing, cooling towers, and industrial processes, reducing freshwater consumption.

Conclusion

A Packaged FRP STP plant is an ideal choice for sustainable wastewater management. With its compact design, high efficiency, corrosion resistance, and low operational costs, it provides a long- term solution for sewage treatment in residential, commercial, and industrial sectors. Investing in a high-quality STP plant ensures regulatory compliance, environmental protection, and cost savings through water recycling. If you are looking for an efficient, durable, and eco-friendly packaged STP plant, choose an FRP

sewage treatment plant today and contribute to a cleaner environment!