Urbanization moves faster than ever in 2025. This unprecedented growth puts enormous pressure on city infrastructure, particularly in managing wastewater safely and sustainably. Conventional wastewater treatment processes have met standard discharge requirements for decades. However, these methods now struggle to meet stricter environmental standards. This makes advanced solutions crucial for water resource sustainability.

Advanced treatment of wastewater has become crucial to ensure clean drinking water access. It prevents ecological damage and helps alleviate climate change by reducing greenhouse gas emissions. The wastewater treatment world evolves quickly with significant breakthroughs. These include membrane bioreactors (MBRs), advanced oxidation processes, and anaerobic digestion technologies. Microbial fuel cells utilize microbial activity to generate bioelectricity during treatment. Microalgae-based systems line up perfectly with circular bioeconomy concepts.

In this piece, we explore four hidden breakthroughs in wastewater treatment technologies that alter the map in 2025. These range from modular MBBR systems that cut operational costs by up to 90% compared to conventional STPs to groundbreaking technologies that handle challenging industrial streams with high biological oxygen demand.

Urban and Industrial Wastewater Challenges in 2025

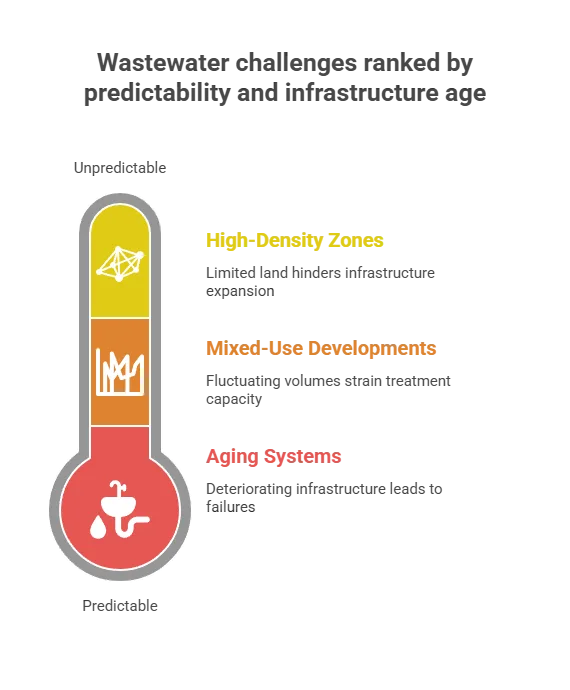

Urban wastewater management faces new challenges in 2025. Population growth, old systems, and unpredictable wastewater flows create a perfect storm that needs innovative solutions beyond traditional treatment methods.

Space constraints in high-density zones

Dense urban areas create major challenges for wastewater treatment infrastructure. Major metropolitan regions just need to deal with limited land for new treatment facilities. Traditional expansion of wastewater treatment plants becomes impractical. This space crunch hits especially hard in packed urban centers where populations keep growing within fixed boundaries.

Modern cities must accomplish more with less space in 2025. Cities that grew more than 10% in the last decade face mounting pressure on their wastewater systems. Budget-friendly compact systems have become crucial. Decentralized solutions work well because they fit into tight spaces and blend with urban surroundings.

Space limits also affect sludge management. Growing restrictions on sludge hauling and land use force facilities to find new disposal methods. This squeeze means facilities must adopt on-site treatment systems that create less sludge and reduce hauling needs.

Aging infrastructure and compliance issues

Deteriorating decades-old wastewater infrastructure stands as the biggest problem in 2025. Water and wastewater systems show critical signs of aging. This leads to inefficiencies, higher costs, and increased environmental and health risks. Structural issues like corrosion, chemical exposure, and material fatigue weaken pipes, treatment systems, and pumps. These problems substantially affect operational reliability.

These aging systems create several critical issues:

- Rising maintenance costs: Emergency repairs and replacements drain budgets and take money from long-term upgrades

- Environmental hazards: System failures contaminate drinking water and ecosystems with pathogens, heavy metals, and new contaminants

- Outdated technologies: Old facilities use inefficient processes that miss current standards and waste energy

Old wastewater infrastructure drives up operational costs. This creates a huge financial burden for municipalities and utility providers. These systems waste more energy and need more chemicals for treatment, even as regulations get stricter.

Variable loads from mixed-use developments

Managing fluctuating wastewater volumes and characteristics emerges as another key challenge in 2025. “Loading” in wastewater treatment means measuring pollutants or contaminants entering the system. These measurements include biochemical oxygen demand (BOD), total suspended solids (TSS), nitrogen, phosphorus, or flow rate.

Hotels, leisure spots, and tourist areas see big changes in wastewater loading throughout the year. These changes include:

- Peak seasons when systems must handle huge surges

- Quiet periods with minimal use that can hurt system performance

- Daily spikes from events that create sudden demands

Mixed-use urban developments create unpredictable wastewater patterns. Studies of municipal treatment plants show secondary effluent BOD variations from 0.2 to 1.1. This range grows as plant treatment levels increase. Power spectrum analyzes show five-day-on and two-day-off patterns for several plants. The amplitude reaches about 20% of the mean load in some cases.

The challenge lies in creating advanced wastewater treatment technologies that handle these changing loads effectively. Systems must maintain treatment quality without exceeding capacity limits. This requires flexible solutions engineered for consistent performance under variable conditions.

Breakthrough 1: Modular MBBR Systems for Compact Installations

MBBR technology stands out as a breakthrough in solving space limitations and treatment efficiency challenges. This biological process uses specialized biofilm carriers suspended in aeration basins. These carriers create a high-density microbial environment that maximizes treatment capacity while keeping the footprint small.

Dual-stage biofilm reactors for BOD and nitrogen removal

Dual-stage configurations mark the rise of MBBR systems and have improved wastewater treatment effectiveness. These systems split the treatment process into two biological stages—aerobic nitrification and anaerobic denitrification. This split helps remove both organic matter and nitrogen compounds more effectively. The combination of pre-denitrification and post-denitrification processes leads to better nitrogen removal than single-stage systems.

Today’s dual-stage MBBR setups blend permeable support bioreactors (PSB) with membrane feeding substrate bioreactors (MFSB) in unified treatment tanks. This setup allows nitrification and denitrification to happen at the same time, which leads to better treatment results. The biofilm carriers offer plenty of surface area for microorganisms to grow, which improves how well the system treats BOD, COD, TSS, and other contaminants.

These systems are impressive because they keep working well even when loads change a lot. Research shows that well-designed MBBR systems can handle organic, hydraulic, and salt shock loadings. They quickly return to normal operation afterward. On top of that, it takes only 3-4 hours to remove both BOD and nitrogen, which means these systems process much more waste than conventional ones.

FRP-based prefabricated units for rapid deployment

FRP prefabricated MBBR units show the next step in modular wastewater treatment. These units are flexible and come in modules that are easy to install, expand, and customize based on site needs. The units are light yet tough, which means quick setup times and better operation.

These systems really shine when it comes to scaling. FRP-based MBBR units fit in standard 40-foot containers, offering powerful solutions for small to medium wastewater projects. This container design works great in tight urban spaces where regular treatment plants won’t fit.

These prefabricated systems handle changing loads well—a vital feature for places with seasonal changes. High-quality FRP STPs come with advanced MBBR technologies that manage unexpected hydraulic and organic loads, especially when you have hospitality setups and mixed-use developments.

IoT-enabled monitoring for real-time compliance

IoT technologies have revolutionized how we manage MBBR systems through up-to-the-minute data analysis. Advanced sensor networks track key water quality markers like pH, dissolved oxygen, electrical conductivity, total dissolved solids, turbidity, and temperature. This constant monitoring helps catch problems and compliance issues right away.

The monitoring systems work in multiple layers—sensing, edge, and application—which helps with smooth data collection, processing, and remote access. This setup controls valves automatically and sends instant alerts so teams can fix issues before contamination happens.

IoT-enabled MBBR systems keep track of past performance data that regulators need. This makes audits easier and helps submit compliance documents to regulatory agencies automatically. UNICEF data shows that about 4,000 people die each day from diseases linked to untreated water, which shows why keeping consistent treatment standards matters so much.

Breakthrough 2: Membrane Bioreactors with Advanced Filtration

MBR technology has become a game-changing solution for advanced wastewater treatment challenges. It combines biological treatment processes with membrane filtration. This combination eliminates the need for secondary clarifiers and sand filters that conventional systems typically use, which significantly improves effluent quality.

Ultrafiltration and nanofiltration integration

UF and NF systems work together to create a reliable treatment framework that handles various contaminants. UF membranes remove suspended solids, bacteria, and most viruses, which makes them an excellent pretreatment method for nanofiltration. NF membranes can selectively remove different salts and help recover resources from high-salinity wastewater.

Research shows that integrated UF-NF systems achieve remarkable contaminant removal rates. They reduce calcium ion content by 91.1%, COD by 97.7%, and TOC by 98.3%. These systems also eliminate trace organic molecules effectively, which produces effluent suitable for reuse. UF membranes typically have pore sizes from 0.01 to 0.1 microns, while NF membrane pores measure approximately 1 nm.

Membrane fouling control using backflush cycles

Membrane fouling remains the biggest problem in MBR operations. It shows up as reduced permeate flux or increased transmembrane pressure. Backwashing cycles provide a mechanical solution that works well for fouling mitigation. Studies reveal that well-implemented backwash procedures can recover up to 100% of the original flux, compared to only 20% recovery without backwash.

The best backwash conditions include flow rates of 1500 mL/min, 5-minute gaps between cycles, and 5-second backwash durations. Different membrane types and wastewater characteristics affect this effectiveness. Some systems use a two-step air backwash that first pushes air into the membrane module before applying a classical backwash, which works better than traditional methods.

Effluent reuse for cooling towers and landscaping

Treated wastewater offers an environmentally responsible alternative to drinking water for non-potable applications. The reused water’s quality must meet specific parameters to avoid equipment damage and health risks. Cooling tower applications face concerns about biohazards, especially when it comes to microorganisms like Legionella.

Reclaimed water’s successful use in cooling systems shows improved water efficiency through higher concentration cycles. Research indicates this approach cuts water consumption by up to 27%, which saves about 797 m³/month in commercial applications. Risk assessment plays a crucial role especially when dealing with contaminants that might affect human health or the environment.

Landscaping applications need proper disinfection and removal of colloidal particles. This ensures the treated water won’t stain surfaces or contain pathogens. Properly treated effluent’s reduced ability to form calcium scale makes it perfect for both cooling towers and irrigation.

Breakthrough 3: Microalgae-Based Nutrient Recovery Systems

Microalgae cultivation treats wastewater in two ways – it removes nutrients and produces valuable biomass. These photosynthetic microorganisms naturally consume nitrogen and phosphorus to generate resource-rich biomass for many applications.

Raceway pond vs. photobioreactor configurations

Microalgae-based wastewater treatment uses two main system configurations: open raceway ponds and closed photobioreactors (PBRs). Raceway ponds are economical with construction costs under 10 €/m². Commercial units can reach 5,000 m² and use minimal energy. These systems need 7-10 days of hydraulic retention time and about 10 m² per equivalent person.

Photobioreactors give better control over growing conditions, produce more biomass, and reduce contamination risks. New membrane photobioreactors (MPBRs) combine membrane technology with PBRs to lower nutrient levels and create concentrated biomass. Modern hybrid systems use PBRs to produce consistent inoculum and raceway ponds to recover nutrients and generate biomass.

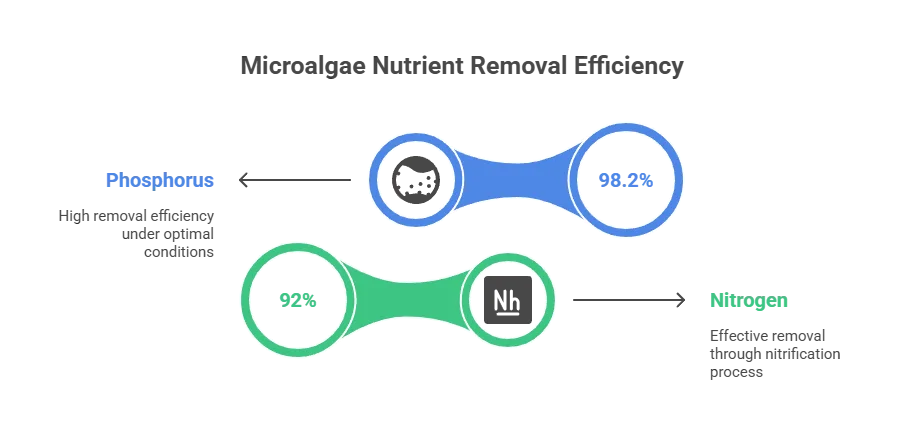

Phosphorus and nitrogen removal efficiency (up to 93%)

Microalgae excel at removing nutrients from wastewater. They can remove up to 98.2% of phosphorus and 92% of nitrogen. Some studies show complete phosphorus removal under optimal conditions.

Nitrogen uptake happens through nitrification where ammonium compounds combine with oxygen to create nitrites and nitrates. Microalgae remove phosphorus through biomass adsorption and calcium phosphate precipitation. Different species show varying results – Chlorella vulgaris reduces BOD by 98.69%, removes 93.14% total nitrogen, and eliminates 98% phosphorus.

Biomass valorization into biofertilizers

Microalgae wastewater treatment produces nutrient-rich biomass with many uses. The biomass works well as a biofertilizer because it contains high nitrogen (36.2 g TN/kg) and phosphorus (11 g TP/kg) levels. These nutrient ratios match perfectly with grass fertilization needs.

This treatment method saves energy. Nitrogen removal needs 1.23 kWh/kg N – 47% less than traditional wastewater treatment. Phosphorus removal uses 29.4 kWh/kg P, which is 2.4 times less energy than conventional methods.

The biomass contains 32-42% proteins, 22-32% carbohydrates, and essential micronutrients like iron, magnesium, zinc, and calcium. These components make it ideal for animal feed, fish feed ingredients, and health supplements containing essential amino acids and polyunsaturated fatty acids.

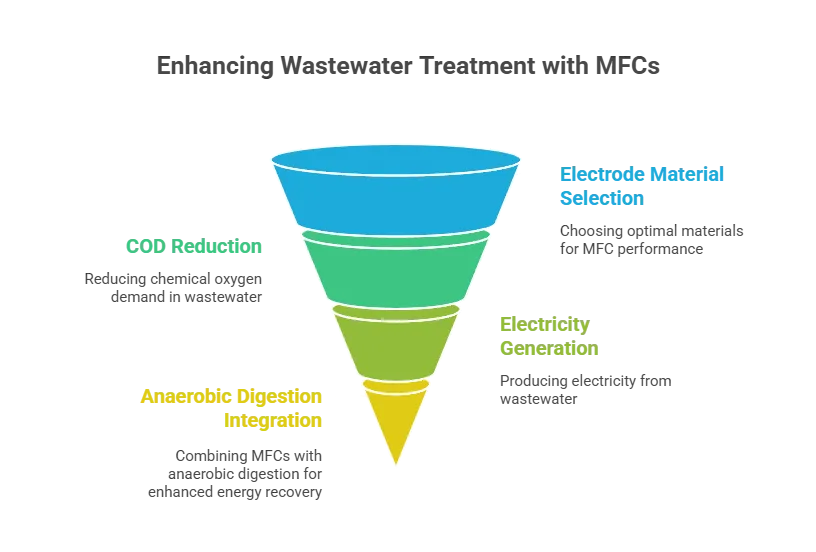

Breakthrough 4: Microbial Fuel Cells for Energy-Positive Treatment

Microbial Fuel Cells (MFCs) are breakthrough innovations in wastewater treatment that use microorganisms to convert organic waste into electricity. These systems treat wastewater and generate clean energy at the same time, which makes them energy-positive solutions.

Electrode materials: carbon felt and graphite mesh

The choice of electrode materials plays a crucial role in MFC performance. Research shows that Graphite Felt (GF) biocathodes reach a maximum current density of 350 mA m^-2 and power density of 109.5 mW m^-2. These numbers are much higher than carbon paper (210 mA m^-2 and 32.7 mW m^-2) and stainless steel mesh (18 mA m^-2 and 3.1 mW m^-2). GF’s superior performance comes from its enhanced catalytic activity in oxygen reduction reactions.

Carbon-based materials make excellent anodes because of their biocompatibility, high conductivity, and surface properties that support bacterial growth. Scientists have improved these materials with polyaniline and gold nanoparticles, which boost power density by up to 52.42%. This improvement creates more practical and efficient systems.

COD reduction and electricity generation in SCMFCs

Single-chamber microbial fuel cells (SCMFCs) show remarkable treatment capabilities. They can remove up to 85% of Chemical Oxygen Demand (COD). The systems produce maximum current densities of 1.0 A m^-2 and power densities of 39.2 mW m^-2 when wastewater concentrations are high.

Current outputs show a strong linear relationship with wastewater concentrations (r^2=0.96). This relationship means SCMFCs could work both as treatment solutions and sensors to monitor industrial wastewater concentrations.

Integration with anaerobic digesters for biogas boost

The most promising development combines MFCs with anaerobic digestion (AD) systems. This cooperative approach improves both processes and maximizes energy recovery while making treatment more efficient.

Research shows that adding submersible MFCs to anaerobic digesters increases methane production by 69% compared to regular AD systems. These combined systems achieve methane yields of 0.32 L/g.COD when glucose concentrations are optimal at 2 g/L.

The integrated system produces total energy outputs of 12.275 kJ/gCOD and achieves impressive removal rates: 88.6% COD, 56.6% total solids, and 80.4% total volatile solids. This combined approach brings us closer to creating self-sufficient wastewater treatment

Conclusion

The year 2025 has brought remarkable changes to wastewater treatment technologies. These changes tackle crucial challenges and create new paths toward sustainable water management. This piece explores four trailblazing solutions that address the most urgent issues in urban and industrial environments.

Modular MBBR systems solve space issues with their compact and efficient designs while maintaining high treatment standards. Their IoT integration provides real-time compliance monitoring and substantially reduces operational risks. Advanced membrane bioreactors equipped with ultrafiltration and nanofiltration capabilities produce exceptional water quality. This water works perfectly in cooling towers and landscaping applications, which helps address the lack of water through smart reuse strategies.

Microalgae-based nutrient recovery systems mark another major step forward. These systems achieve 93% phosphorus and nitrogen removal efficiency and produce valuable biomass for biofertilizers. This approach turns waste management into resource recovery and fits perfectly with circular economy principles. Microbial fuel cells show similar promise by converting organic waste directly into electricity and reducing COD levels by 85%.

These innovations tackle three main challenges: aging infrastructure, space limitations, and variable load management. Their adaptable nature lets them fit into existing systems without major infrastructure changes. They handle fluctuating loads from mixed-use developments well and perform consistently whatever the seasonal or daily variations.

The future looks bright as these technologies expand in a variety of settings. Systems integration, especially MFCs with anaerobic digesters, points to treatment facilities that can sustain themselves by generating energy while cleaning water. Some challenges in optimization and cost remain. Yet these breakthrough technologies are without doubt the future of wastewater treatment. They create a world where water purification, resource recovery, and energy generation happen at once, turning waste into valuable resources.

Key Takeaways

The wastewater treatment industry is experiencing revolutionary changes in 2025, with four breakthrough technologies transforming how we manage water resources while addressing space constraints, aging infrastructure, and variable loads.

- Modular MBBR systems reduce operational costs by 90% compared to conventional plants while fitting into compact urban spaces with IoT-enabled real-time monitoring.

- Advanced membrane bioreactors achieve 97.7% COD removal and enable water reuse for cooling towers and landscaping, reducing freshwater consumption by up to 27%.

- Microalgae systems remove up to 93% of nutrients while producing valuable biomass for biofertilizers, creating a circular economy approach to waste management.

- Microbial fuel cells generate electricity while treating wastewater, achieving 85% COD reduction and creating truly energy-positive treatment facilities.

- Integration of technologies maximizes efficiency – combining MFCs with anaerobic digesters increases methane production by 69% while maintaining high treatment standards.

These innovations represent a paradigm shift from traditional waste treatment to resource recovery systems that simultaneously purify water, generate energy, and produce valuable byproducts. The modular, scalable nature of these technologies makes them ideal for retrofitting existing infrastructure without complete overhauls, positioning the industry for sustainable growth in increasingly urbanized environments.

FAQs

Q1. What are the main challenges facing wastewater treatment in 2025?

The primary challenges include space constraints in high-density urban areas, aging infrastructure leading to compliance issues, and managing variable loads from mixed-use developments.

Q2. How do modular MBBR systems address space constraints in wastewater treatment?

Modular MBBR systems use compact, efficient designs that maintain high treatment standards while fitting into limited urban spaces. They also feature IoT integration for real-time compliance monitoring.

Q3. What advantages do membrane bioreactors offer in wastewater treatment?

Membrane bioreactors with advanced filtration achieve exceptional water quality, enabling water reuse for cooling towers and landscaping. They can reduce water consumption by up to 27% in some applications.

Q4. How do microalgae-based systems contribute to nutrient recovery in wastewater treatment?

Microalgae-based systems can remove up to 93% of phosphorus and nitrogen from wastewater while producing valuable biomass that can be used as biofertilizer, aligning with circular economy principles.

Q5. What is the potential of microbial fuel cells in wastewater treatment?

Microbial fuel cells can generate electricity while treating wastewater, achieving up to 85% COD reduction. When integrated with anaerobic digesters, they can increase methane production by 69%, moving towards energy-positive treatment facilities.