Poor sewage plant installation can create a physical mess and legal headaches. You can’t cut corners in wastewater management.

Packaged sewage treatment plants are a vital solution to on-site wastewater management. These pre-manufactured units arrive ready for installation and need minimal site preparation. The compact systems treat wastewater through physical, biological, and chemical processes. This makes them perfect for residential, commercial, or small-scale industrial properties. The installation needs careful planning and proper positioning so wastewater drains away from high-traffic areas.

This piece will guide you through the steps to install a packaged sewage treatment plant correctly. We’ll cover everything from picking the right location to meeting regulatory requirements. You’ll learn the installation process step by step and get useful maintenance tips. We’ll also help you understand different types of STP plants and how to pick the right system that fits your needs.

Understanding Packaged Sewage Treatment Plants

Packaged sewage treatment plants (PSTPs) have transformed on-site wastewater management through their smart, compact design. These self-contained systems provide an innovative way to treat wastewater in settings of all types where standard infrastructure isn’t possible.

What is a sewage treatment plant?

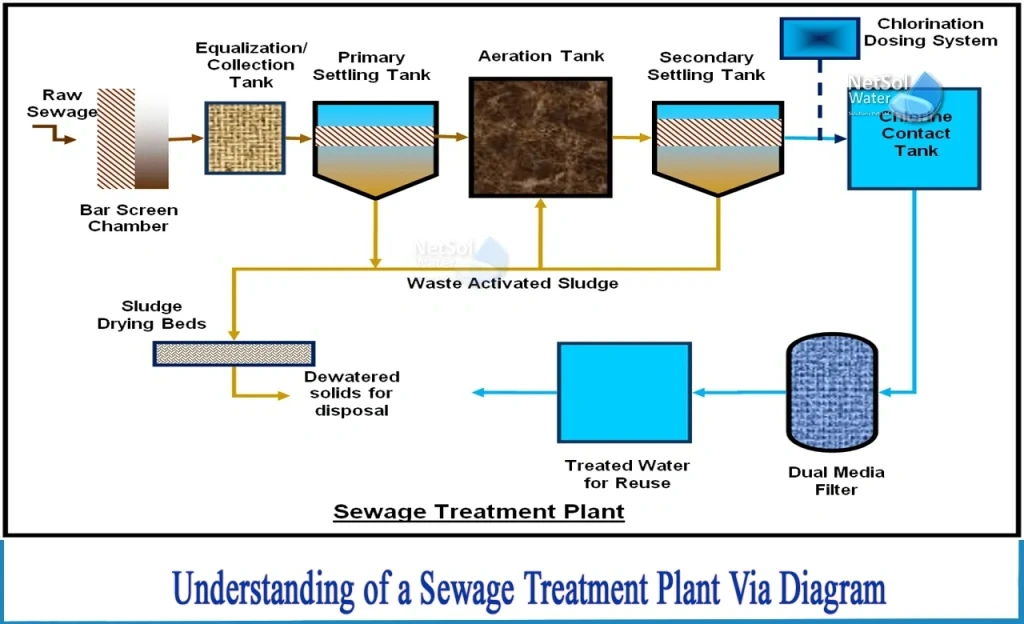

A sewage treatment plant (STP) removes contaminants from wastewater to make it safe for environmental discharge or reuse. The treatment process works through multiple stages that purify wastewater from homes, businesses, and industrial facilities.

Every sewage treatment plant follows these treatment phases:

- Primary treatment: Removes large solids and debris through screening and sedimentation

- Secondary treatment: Uses biological processes to break down organic matter

- Tertiary treatment: Provides advanced purification for higher quality effluent

The biological wastewater treatment process uses aerobic bacteria to decompose organic contaminants in an aeration chamber. This creates clarified liquid that’s safe for discharge or additional treatment.

How packaged STPs differ from traditional systems

Packaged STP plants offer unique benefits compared to conventional sewage treatment plants that need extensive construction and space:

Pre-fabricated and modular: These plants arrive as complete, factory-assembled units that need minimal site preparation. You can install them in days instead of months.

Space efficiency: Their compact design makes them perfect for space-restricted locations. They need about half the space of conventional systems.

Mobility and flexibility: You can relocate many packaged units easily, unlike permanent traditional installations.

Operational differences: Traditional STPs need expert operators and daily checks. Packaged systems feature automation that needs less maintenance. Modern PSTPs include smart features like SCADA monitoring and automated controls for smooth operation.

Cost considerations: Traditional systems cost more upfront due to extensive construction. Packaged STPs save money during installation thanks to their pre-fabricated design.

Types of STP plant and their applications

The market offers several packaged sewage treatment technologies:

Activated Sludge Systems: These systems use aerobic bacteria to break down organic matter in wastewater. About 70% of municipalities choose this system because it handles large volumes well.

Sequencing Batch Reactors (SBR): SBRs process wastewater in batches using one tank for multiple treatment stages. They create high-quality effluent through five stages: fill, react, settle, decant, and idle.

Membrane Bioreactors (MBR): These units combine biological treatment with membrane filtration to produce superior effluent. They work great for municipal and industrial needs.

Moving Bed Biofilm Reactors (MBBR): MBBR technology supports biofilm growth on plastic carriers. It mixes conventional activated sludge with biofilm media to improve treatment.

SUSBIO ECOTREAT: This advanced packaged STP uses a dual treatment process that combines physical and biological methods. It runs quietly and uses minimal energy. The system comes pre-engineered and assembled off-site for quick deployment. SUSBIO ECOTREAT’s compact footprint helps preserve natural spaces in urban areas where land comes at a premium.

Packaged STPs work well in a variety of settings—from residential complexes and hotels to hospitals, schools, and commercial buildings. They prove especially useful in remote locations, temporary setups, or projects with strict deadlines.

Key Considerations Before Installation

You need to think over several important factors before starting the installation of a packaged STP plant. Good planning at this stage will help avoid getting pricey mistakes and give your sewage treatment plant years of smooth operation.

Site selection and space requirements

The location you pick for your sewage plant treatment system will affect its performance in the long run. You should start with a full site evaluation to check soil conditions, groundwater levels, and how close it is to existing infrastructure. Bad site planning can cause structural failures, make maintenance difficult, and might contaminate the environment.

For optimal installation, avoid:

- Low-lying areas prone to flooding or water accumulation

- Residential basements (STPs should never be installed here)

- Locations with inadequate drainage

Modern packaged systems can be safely installed under driveways, clubhouses, and well-ventilated parking lots. These systems need about 50% less space than traditional treatment plants, which makes them perfect for properties where land is limited.

Regulatory permissions and discharge consent

Strict regulations govern the installation and operation of sewage treatment plants. You must get all necessary approvals before installation begins.

Two main environmental acts control sewage treatment plants in India at the federal level:

- The Water (Prevention and Control of Pollution) Act, 1974

- The Environment (Protection) Act, 1986

Property owners need two key permissions:

- Consent for Establishment (CFE) – Required before construction begins

- Consent for Operation (CFO) – Needed before commissioning the STP

The approval process needs detailed technical documentation, including plant designs, flow diagrams, and treatment processes. The State Pollution Control Board reviews applications to check if proposed systems meet environmental standards.

Immediate monitoring systems must track effluent quality, and SPCBs conduct regular audits to check compliance. Not following these regulations can lead to penalties, facility shutdowns, and legal issues.

Power supply and ventilation planning

A packaged sewage treatment plant needs reliable power to run continuously. The STP panel must have continuous electric incoming supply with proper earthing before installation.

Good ventilation plays a vital role since wastewater treatment plants produce explosive, toxic, and corrosive gasses when organic matter breaks down. The facility’s design must follow NFPA 820 standards to lower these risks.

NFPA 820 standards require these ventilation features:

- Continuous mechanical ventilation with both supply and exhaust

- Cross-ventilation with supply and exhaust on opposite walls

- Proper air changes per hour (ACH) based on space classification

- High and low air pickup points to capture both lighter and heavier gasses

The right ventilation can reduce hazardous classification levels or declassify spaces in many processes. Ventilation systems should include mechanical supply and exhaust that runs non-stop to maintain safety standards.

A careful review of these factors will help your packaged sewage treatment plant run smoothly, meet all regulations, and work safely throughout its life.

Step-by-Step Installation Process

A packaged sewage treatment plant needs proper installation with careful attention to detail. These six critical steps will give a reliable system that works well for years to come.

1. Inspect and prepare the tank

You should check the delivered tank for any transport damage before starting the installation. Get into all components carefully since manufacturers typically reject damage claims after installation. Make sure the tank has correct invert depths that match your existing pipework. The manufacturer’s installation guide has specific requirements for your model, so read it completely first.

2. Excavate and install the base

Start by clearing trees, roots, and debris from the installation area. Your hole should fit both the tank and recommended backfill material. Think over drainage falls—usually 1 in 60/70 between house and tank. A solid, stable concrete base prevents stress on the tank during operation. Let this foundation set properly.

3. Position and level the tank

After the base sets, use the manufacturer-recommended lifting system to lower the tank into position. The inlet and outlet orientations should match your planned connections correctly. The tank needs to sit level on all sides for proper wastewater flow—a carpenter’s level helps verify this. Add or remove sand or gravel beneath the tank as needed.

4. Connect inlet and outlet pipes

The next step connects your property’s plumbing to the tank’s inlet pipe. Use a slight slope (1/8 to 1/4 inch per foot) that allows gravity flow. The outlet pipe needs proper slope to move treated wastewater to its discharge point. Use strong waterproof sealants at all joints to stop leaks. Many manufacturers suggest inspection chambers before and after the treatment plant to make maintenance easier.

5. Backfill and secure the system

Backfilling keeps the tank firmly positioned in the ground. The manufacturer’s specs tell you which materials work best—usually sand, gravel, or concrete. Place fine-grained loose soil around the tank in a 60 cm radius up to ground level. This approach reduces surface subsidence around the system.

6. Final electrical and manhole setup

The last step involves electrical connections based on manufacturer guidelines. Control panels and electrical distribution boards should stay in flood-safe locations. Your control panel needs a schematic diagram with labels in English and other relevant languages. High-level alarms in pump sumps should connect to a monitored location. Install manhole covers that direct vehicle traffic loads to surrounding ground instead of the system itself.

Document and photograph each step for future maintenance needs.

Post-Installation Maintenance and Troubleshooting

You retain control of your newly installed sewage treatment plant by maintaining it properly. This will give a longer lifespan and streamline processes. Regular maintenance prevents things from getting pricey and keeps you compliant with environmental regulations.

Routine checks and sludge removal

Your sewage plant treatment system needs professional servicing at least once a year. Maintenance professionals will inspect components like air compressors, pumps, diffusers, and blowers to check for wear. They also monitor the bacteria that break down waste.

The system’s efficiency depends on proper sludge management. Most manufacturers suggest yearly emptying, though budget treatment plants might need more frequent cleaning. Your plant’s efficiency can drop by 30% if sludge builds up too much. You need immediate sludge removal when it fills about 50% of the primary chamber. The process involves:

- Manual removal with shovels after solids dewater sufficiently

- Using knife gate valves to push choked sludge back into the clarifier

- Getting professional desludging services from licensed companies

Common issues and how to fix them

Sewage plant treatment systems can face operational challenges even with careful installation. High ammonia often means not enough oxygen—keep dissolved oxygen above 1.0 mg/L. Bad smells usually mean anaerobic conditions, so you’ll need more aeration and thorough cleaning.

Equipment problems need attention quickly. Blowers or pumps making strange noises—grinding, squealing, or too much vibration—signal upcoming failure, usually from worn bearings or electrical problems. Floating solids or poor clarification show process imbalances, often from incorrect Mixed Liquor Suspended Solids levels or poor sludge return.

When to call a professional

You can handle routine maintenance, but some situations need expert help. Call qualified technicians right away if:

- High-level or fault alarms go off (even with temporary muting)

- Effluent quality issues persist, especially with BOD/COD levels

- Sludge overflows in clarifiers or around the system

- Effluent parameters suddenly spike beyond limits

- Power supply affects continuous operation

Note that emergency cleanup costs 10-15 times more than regular maintenance. British Water accredited professionals should handle annual servicing to meet regulatory requirements.

Why SUSBIO ECOTREAT is the Best Packaged STP Plant

SUSBIO ECOTREAT leads the next wave of packaged sewage treatment technology with its innovative engineering and practical design that sets it apart from competitors.

Dual treatment process for higher efficiency

SUSBIO ECOTREAT combines a sophisticated dual-treatment process that merges anaerobic and aerobic methods. The system pairs Moving Bed Biofilm Reactor (MBBR) and Sequencing Batch Reactor (SBR) technologies to achieve superior wastewater purification. Wastewater flows through multiple stages: oil separation, sedimentation, anaerobic processing, moving bed treatment, secondary sedimentation, and disinfection. The pre-anoxic tank reduces total nitrogen content by up to 80% without chemical additives.

Energy savings and noiseless operation

The system achieves remarkable efficiency by using 90% less electricity than conventional sewage treatment plants. Advanced diaphragm air pumps with flexible membrane movement keep noise levels below 50 decibels, unlike traditional noisy rotational mechanisms. The system optimizes energy consumption through variable frequency drives that adjust aeration based on live load conditions.

Plug-and-play design for easy setup

SUSBIO ECOTREAT ships as a prefabricated unit ready for quick installation without complex construction work. Users can choose between two configurations: Capsule Type (1-20 KLD) for smaller applications and Cylinder Type (20-500 KLD) for larger projects. The system’s compact design needs 50% less space than traditional systems.

Low maintenance and long-term durability

The system’s high-quality fiber-reinforced plastic (FRP) construction provides exceptional strength and resists corrosion, backed by a 10-year warranty. Users can run the system maintenance-free for over five years, thanks to self-cleaning mechanisms for membranes and pumps. Smart IoT integration allows remote monitoring and predictive maintenance.

Conclusion

Packaged sewage treatment plants mark the most important advancement in wastewater management technology. These plants are a great way to get solutions for areas that can’t access centralized systems. This piece explores everything in these systems, from their operation to successful installation.

The right site selection creates the foundation to make STP work properly. Your system must meet environmental standards to avoid legal issues. A careful approach to the six-step installation process will give you a system that serves your property for years.

Your system needs proper care after installation. The system’s lifespan improves with regular checks, timely sludge removal, and quick fixes to problems that pop up. Complex issues beyond simple troubleshooting need professional help.

SUSBIO ECOTREAT stands out among packaged sewage treatment options. The system features an innovative dual treatment process, remarkable energy efficiency, and intuitive design. Its noiseless operation, low maintenance needs, and compact size make it perfect for properties of all types. On top of that, its corrosion-resistant construction lasts longer than conventional alternatives.

Note that taking shortcuts during planning, installation, or maintenance leads to system failures, environmental damage, and costly repairs. A well-laid-out and properly maintained packaged sewage treatment plant protects our water resources and public health while providing reliable service.

The fundamental change toward packaged STP plants, especially advanced systems like SUSBIO ECOTREAT, shows growing awareness about green, efficient wastewater management solutions. Without doubt, these systems will evolve further and offer even greater benefits for residential, commercial, and industrial uses in the future.

Key Takeaways

Installing a packaged sewage treatment plant requires careful planning, proper execution, and ongoing maintenance to ensure efficient wastewater management and regulatory compliance.

• Site preparation is critical: Choose locations with proper drainage, avoid basements, and secure regulatory approvals (CFE and CFO) before installation begins.

• Follow the 6-step installation process: Inspect tank, excavate base, position and level, connect pipes, backfill securely, and complete electrical setup for optimal performance.

• Annual maintenance prevents costly failures: Schedule professional servicing, monitor sludge levels, and address issues like high ammonia or equipment malfunctions promptly.

• SUSBIO ECOTREAT offers superior efficiency: Dual treatment process, 90% energy savings, noiseless operation, and 5+ years maintenance-free operation make it ideal.

• Regulatory compliance is mandatory: Obtain proper permits from State Pollution Control Boards and maintain real-time monitoring systems to avoid penalties.

Proper installation and maintenance of packaged STPs protect water resources while providing reliable wastewater treatment for residential, commercial, and industrial applications. Advanced systems like SUSBIO ECOTREAT represent the future of sustainable wastewater management with their compact design and exceptional performance capabilities.

Frequently Asked Questions

Q1. What are the main advantages of packaged sewage treatment plants?

Packaged sewage treatment plants offer several benefits, including space efficiency, quick installation, mobility, and lower upfront costs compared to traditional systems. They are pre-fabricated, modular units that require minimal on-site preparation and can be installed within days.

Q2. How often should a packaged sewage treatment plant be serviced?

It is recommended to service a packaged sewage treatment plant at least once a year. This annual maintenance typically involves inspecting components like air compressors, pumps, and diffusers, as well as checking the health of waste-breaking bacteria.

Q3. What permissions are required before installing a packaged sewage treatment plant?

Before installing a packaged sewage treatment plant, you need to obtain two key permissions: Consent for Establishment (CFE) before construction begins, and Consent for Operation (CFO) before commissioning the plant. These are typically issued by the State Pollution Control Board.

Q4. How does the SUSBIO ECOTREAT system differ from conventional packaged STPs?

SUSBIO ECOTREAT uses a dual treatment process combining MBBR and SBR technologies, consumes 90% less electricity than conventional systems, operates below 50 decibels, and can function maintenance-free for over five years. It also features a compact design and IoT integration for remote monitoring.

Q5. What are some common issues with packaged sewage treatment plants and how can they be addressed?

Common issues include high ammonia levels, foul odors, and equipment malfunctions. High ammonia can be addressed by ensuring proper oxygen levels, foul odors often require increased aeration and cleaning, while equipment issues may need professional intervention. Regular maintenance and prompt attention to these problems can prevent more serious failures.