Aeration tanks are the heart of wastewater treatment systems. These tanks host vital biological processes that break down organic pollutants. The large basins combine wastewater with air to promote microbial growth and reduce the biological oxygen demand (BOD) of the effluent by a lot. The proper design of these tanks affects treatment efficiency, which makes engineering specifications vital.

The optimal performance of aeration tanks depends on specific technical requirements. Engineers should design tank depths between 10-30 feet, while horizontally mixed tanks need a minimum depth of 5.5 feet. The mixed liquor must maintain a dissolved oxygen concentration of at least 2.0 mg/L to work effectively. Wastewater kinetic coefficients and the design model affect the tank’s volume by a lot.

This piece explores aeration tanks’ working principles and design recommendations that achieve 99% treatment efficiency. The text also gets into optimization strategies for wastewater treatment facilities. Oxygen transfer efficiency, mixing intensity, and sludge management are the foundations of effective aeration systems. New facility designers should know that running a pilot plant helps determine specific wastewater kinetics, which leads to accurate sizing of aeration tanks.

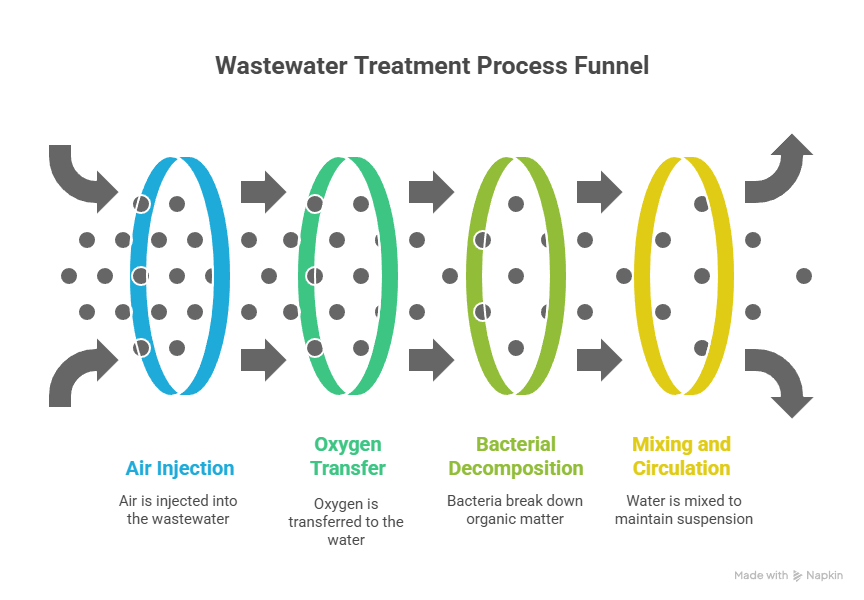

Aeration Tank Working Principle and Process Flow

The biological treatment process in aeration tanks depends on three mechanisms that work together to clean wastewater effectively. These mechanisms create the perfect environment where microorganisms can thrive and break down contaminants.

Air Injection and Oxygen Transfer in Diffused Systems

Diffused aeration pushes compressed air below the wastewater surface through special diffusers. Oxygen bubbles rise through the wastewater and increase the dissolved oxygen content needed for biological treatment. Fine bubble diffusers (< 2mm bubble size) work better with oxygen transfer efficiencies of 5-7% per meter of water depth. Coarse bubble systems (> 2mm) achieve only 2-4.5% per meter. Fine bubble systems also give better aeration efficiencies when you measure oxygen mass transferred per unit power per unit time.

The system pumps air through diffusers at the tank bottom and creates a uniform bubble pattern that maximizes contact between air and wastewater. This process is vital because it keeps dissolved oxygen levels high enough for aerobic bacteria to break down organic pollutants. Tank depth, bubble size, and diffuser arrangement all affect how well oxygen transfers into the water.

Bacterial Decomposition of Organic Matter

Aerobic bacteria do the heavy lifting in aeration tanks. They use oxygen to turn organic pollutants into harmless byproducts. Scientists have found about 45 bacterial species in aeration tanks. Bacillus leads the pack as the dominant genus with twenty-one isolates. These microorganisms cluster into biological flocs that absorb and digest organic contaminants.

Bacteria use oxygen to break down carbon-containing compounds into carbon dioxide and water. The process slows down without enough dissolved oxygen. This creates septic conditions that smell bad and don’t fully convert pollutants. Proper oxygen levels will directly affect how well the treatment works.

Mixing and Circulation to Maintain Suspension

Aeration systems do more than just add oxygen. They create mixing patterns that keep bacterial flocs floating in the wastewater. This constant motion maximizes contact between microorganisms and organic matter. Good mixing stops solids from settling too early and spreads oxygen evenly through the tank.

Each mixing arrangement has its benefits. Floor layout diffusers mix efficiently because they maintain an acceptable minimum flow rate/density relationship. In-line or spiral flow arrangements use the air lift effect differently. They create rotating water movement that generates high sweeping velocities across the tank floor. This circulation helps keep solids suspended, which lets bacteria break down more contaminants.

Designing for 99% Treatment Efficiency

Wastewater treatment plants just need precise engineering calculations and technical specifications to achieve optimal performance. Well-designed aeration tanks can deliver up to 99% treatment efficiency when operators carefully control the key parameters.

Aeration tank depth and volume recommendations

The right dimensions are the foundations of effective aeration tank design. The tank depth works best between 3 to 4.5 meters to give optimal aeration efficiency. The width should stay between 5 and 10 meters to control mixing effectiveness. A balanced operation requires the width-to-depth ratio between 1.2 and 2.2. The tank length should be more than 30 meters but less than 100 meters to maintain proper flow dynamics.

Tank volume requirements depend directly on MLSS concentration. Plug flow systems typically work with MLSS values of 2000-3000 mg/L, while completely mixed systems run effectively at 3000-5000 mg/L. MLSS concentrations rarely go above 5000 g/m³ because of oxygen transfer limitations.

Maintaining 2.0 mg/L dissolved oxygen levels

Most treatment plants aim to keep dissolved oxygen at 2.0 mg/L as the ideal setpoint. This level will give microorganisms enough oxygen throughout the biological floc. Bacteria in the floc center might die from oxygen deprivation if DO levels drop below 2.0 mg/L, which leads to floc breakdown and treatment failure.

High DO levels waste energy without any treatment benefits. Aeration makes up 30-60% of a plant’s total electrical power usage, so precise DO control streamlines processes. Plants can cut energy costs by up to 50% with automated DO measurement systems.

Hydraulic retention time and flow balancing

Engineers calculate Hydraulic retention time (HRT) using the formula HRT = V/Q, where V represents tank volume and Q shows influent flow rate. Effective HRT ranges from 5 to 24 hours in wastewater treatment. The system risks washout with shorter retention times, while longer periods might reduce treatment efficiency.

Flow balancing boosts performance by storing peak flows and releasing them gradually. This approach spreads hydraulic loads over several days, especially during predictable high-use events. Balanced flows improve biological treatment effectiveness and reduce energy consumption.

Optimizing Aeration Tank Performance in Wastewater Treatment

Aeration tanks work best when operators pay attention to essential operational parameters. The perfect balance comes from managing oxygen delivery, sludge handling, and automated control systems.

Oxygen transfer efficiency (OTE) measures

OTE affects treatment performance and energy costs. Diffused aeration systems work best with OTE values between 2 to 17 grO2/m3air. Oxygen absorption percentages typically range from 0.45-5.4%. Tank depth’s effect on OTE is a big deal as it means that increasing depth from 1.0 to 4.0 m can improve oxygen absorption from 15% to 40%. Higher coverage ratios of diffuser area lead to better efficiency.

Sludge buildup and removal frequency

Good sludge management prevents system failures and maintains treatment capacity. The sludge volume index (SVI) above 150 indicates sludge bulking. Operators can determine the right removal timing by monitoring with sludge judges and pressure sensors. Excess sludge blocks oxygen flow and creates backpressure that increases blower energy consumption. Regular sludge level measurements and diffuser cleaning prevent clogging.

Up-to-the-minute aeration control systems

Advanced control systems cut aeration energy consumption by 15-30%. These systems use dissolved oxygen sensors and automation to adjust aeration rates based on current conditions. A case study showed that up-to-the-minute monitoring and control cut nutrients by 90% and energy consumption by 95%. Modern systems now use machine learning to set dissolved oxygen targets with minimal operator input.

Integrating Paddle Dryers for Sludge Management

Sludge management is a vital final step after processing in aeration tanks. Paddle dryers are a great way to get sophisticated treatment for excess sludge that wastewater treatment generates.

Sludge drying capacity and moisture reduction

Paddle dryers excel at removing moisture. They can reduce sludge water content from 80% to just 10%. This change turns wet sludge into stable biosolids that feel like soil. Research shows moisture content dropped from 63.1% to 51.6% after processing. Raw sludge in municipal wastewater plants usually contains 93-99% water. The final product reaches about 90% solid content after thickening, dewatering and drying.

Energy-efficient paddle dryer configurations

The system’s dual counter-rotating shaft design with intermeshing paddles gives uniform heating and the best moisture reduction. These systems work at lower temperatures between 100-250°C. They use conduction instead of convection, which means minimal energy waste. Paddle dryers use 30-40% less energy than belt or fluidized bed dryers. The systems can reuse waste heat from boilers to streamline processes even more.

Pre-treatment and temperature control best practices

Sludge goes through dewatering in filter presses or centrifuges to reach 18-25% dry solids before entering paddle dryers. The drying chamber needs multiple detection points to monitor temperature distribution. Modern systems use automated control cabinets that adjust steam flow when temperatures get too high. Safety features include emergency water sprays that turn on automatically if temperatures spike.

Conclusion

The success of wastewater treatment systems depends on how well engineers design the aeration tanks. In this piece, we looked at how precise engineering specs help achieve treatment efficiencies up to 99%.

Tank dimensions play a crucial role. The ideal conditions for oxygen transfer and proper mixing patterns need depths between 3-4.5 meters and widths between 5-10 meters. Dissolved oxygen levels must stay at or above 2.0 mg/L so healthy bacterial communities can thrive within biological flocs.

The time wastewater spends in the tank is another key factor, usually 5-24 hours based on its characteristics. When you combine this with good flow balancing, microorganisms get enough time to break down organic pollutants.

Fine bubble diffusion systems are the quickest way to boost oxygen transfer efficiency and cut down energy use. Modern control systems also improve performance because they maintain ideal conditions without operators checking constantly.

The treatment process wraps up with sludge management. Paddle dryers offer a budget-friendly way to reduce moisture content from 80% to as low as 10%. This final step turns waste products into manageable biosolids.

Engineers need to balance biological needs, engineering limits, and operational efficiency to create successful aeration tanks. These guidelines help deliver consistent treatment performance while keeping energy costs low. The principles we covered are the foundations for designing new facilities and upgrading existing wastewater treatment plants.

Key Takeaways

These expert engineering guidelines provide the essential framework for designing high-performance aeration tanks that consistently achieve 99% treatment efficiency in wastewater treatment systems.

• Maintain precise tank dimensions: Design depths of 3-4.5 meters and widths of 5-10 meters to optimize oxygen transfer and mixing patterns for maximum treatment effectiveness.

• Keep dissolved oxygen at 2.0 mg/L minimum: This critical threshold ensures bacterial survival throughout biological flocs and prevents system failure from oxygen deprivation.

• Use fine bubble diffusers for efficiency: These systems achieve 5-7% oxygen transfer per meter depth compared to 2-4.5% for coarse bubble systems, reducing energy costs significantly.

• Implement automated control systems: Real-time monitoring and control can reduce aeration energy consumption by 15-30% while maintaining optimal treatment performance.

• Integrate paddle dryers for sludge management: These systems reduce sludge moisture from 80% to 10% using 30-40% less energy than conventional drying methods.

When properly implemented, these design principles create a comprehensive wastewater treatment system that balances biological requirements with operational efficiency, ensuring consistent performance while minimizing energy costs and maintenance requirements.

Frequently Asked Questions

Q1. What is the optimal depth for an aeration tank in wastewater treatment?

The optimal depth for an aeration tank typically ranges from 3 to 4.5 meters. This depth range ensures efficient oxygen transfer and proper mixing, which are crucial for effective wastewater treatment.

Q2. How much dissolved oxygen should be maintained in an aeration tank?

It’s recommended to maintain a minimum dissolved oxygen concentration of 2.0 mg/L in the aeration tank. This level ensures that microorganisms throughout the biological floc receive sufficient oxygen for effective treatment.

Q3. What are the advantages of using fine bubble diffusers in aeration tanks?

Fine bubble diffusers (< 2mm bubble size) provide higher oxygen transfer efficiencies of 5-7% per meter of water depth, compared to 2-4.5% for coarse bubble systems. This increased efficiency leads to improved treatment performance and reduced energy consumption.

Q4. How can real-time control systems improve aeration tank performance?

Real-time aeration control systems can reduce energy consumption by 15-30%. These systems use dissolved oxygen sensors and automation to adjust aeration rates based on real-time conditions, optimizing treatment efficiency while minimizing energy use.

Q5. What role do paddle dryers play in sludge management after aeration treatment?

Paddle dryers are used for treating excess sludge generated during wastewater treatment. They can reduce sludge moisture content from 80% to as low as 10%, transforming wet sludge into stable biosolids. Paddle dryers are also more energy-efficient than conventional drying methods, consuming 30-40% less energy.