Aeration tanks function as the heart of modern sewage treatment plants and play a pivotal role in wastewater’s biological treatment process. The final results of clean water often catch our attention, but bacteria cannot biodegrade incoming organic matter properly without proper aeration. The activated sludge process relies on aeration as its most vital component.

A closer look at water treatment’s aeration process reveals these specialized tanks create an environment where wastewater stabilizes during the first treatment stages. The sewage treatment plant’s aeration tanks remove soluble contaminants, toxic chemicals, and harmful pathogens from wastewater. On top of that, they help reduce the biological oxygen demand (BOD) of the wastewater while preventing unwanted contamination and boost the growth of beneficial aerobic bacteria. This piece will explore how aeration tanks work, the different types of aeration systems, optimization strategies, and their integration with other treatment processes.

How Aeration Tanks Enable Biological Treatment in STPs

The biological treatment in sewage systems shows us a remarkable microbial ecosystem. Aeration tanks create perfect conditions where organic pollutants break down naturally. These specialized tanks help the biological oxidation of organic matter through aerobic microbial action that turns harmful substances into simpler, less toxic compounds.

Aeration tank in sewage treatment plant: Simple function

An aeration tank creates an environment where wastewater stabilizes through biological means. Sewage flows through these tanks and mixes with air or pure oxygen to generate an activated sludge process. The process helps aerobic microorganisms grow and stay active. These organisms break down organic compounds and digest them before they’re removed through sedimentation and filtration. The tanks also remove soluble contaminants, toxic chemicals, and harmful pathogens from wastewater, making them crucial for bacterial biodegradation.

Role of oxygen in microbial decomposition

Oxygen works as the terminal electron acceptor in microbial metabolic processes. Blowers or mixers supply oxygen to aerobic bacteria that use it to metabolize organic matter into carbon dioxide, water, and energy. This aerobic activity helps microorganisms grow and reproduce, which keeps their population stable in the tank. The right dissolved oxygen levels let beneficial bacteria break down organic solids that cause high BOD. Treatment plants usually keep dissolved oxygen at about 2 mg/L when using atmospheric air. Systems using pure oxygen can run at 4-10 mg/L.

Activated sludge process and BOD reduction

The activated sludge process stands among the most common ways to reduce biochemical oxygen demand (BOD) in wastewater. Activated sludge contains naturally occurring aerobic microorganisms—mainly bacteria, protozoa, and fungi—that use BOD as food. These microorganisms create biological flocs that metabolize organic materials, which turn into carbon dioxide, nitrates, sulfates, and additional biomass. The process reduces organic pollutants by a lot, which improves water quality. E. coli helps remove nutrients like nitrogen and phosphorus through biological nutrient removal (BNR). Bacillus species help with denitrification and hydrocarbon degradation.

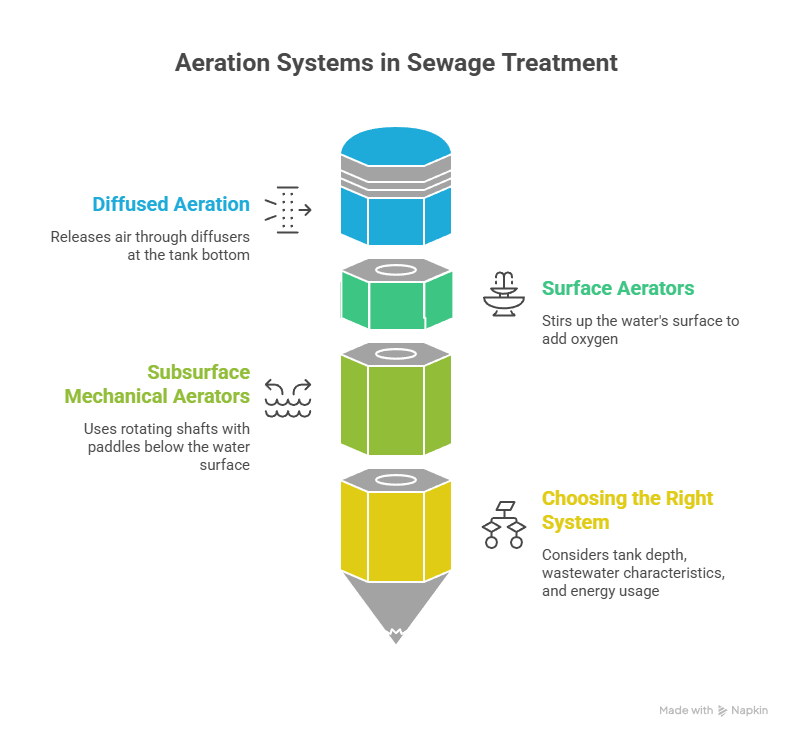

Types of Aeration Systems Used in Sewage Treatment

The right aeration system plays a crucial role in wastewater treatment plant design. Different technologies bring their own set of benefits based on operational needs. These systems vary in how they transfer oxygen, use energy, and mix the contents.

Fine vs coarse bubble diffused aeration

Diffused aeration systems work by releasing air through diffusers at the tank bottom. Bubbles rise through the wastewater to create the aeration effect. Fine bubble diffusers create smaller bubbles (1-3mm in diameter) that rise slower and stay in contact with wastewater longer. This gives them better oxygen transfer efficiency – 5-7% per meter of submersion compared to coarse bubble systems at 2-4.5%. The standard aeration efficiency numbers are a big deal as it means that fine bubble systems achieve 4.0-7.0 lb O2/hp-hr while coarse bubble systems reach only 1.5-3.0 lb O2/hp-hr.

Fine bubble diffusers need more upfront investment and can clog more easily. Coarse bubble diffusers shine in high-solids environments because their larger openings resist fouling and mix contents better.

Surface aerators vs subsurface mechanical aerators

Surface aerators add oxygen by stirring up the water’s surface. You’ll find floating devices with impellers, paddlewheels, and fountains that work best in tanks less than 8 feet deep. These systems add large amounts of oxygen at the surface quickly but mostly affect the top water layers.

Subsurface mechanical aerators use rotating shafts with multiple paddles below the water surface. Deep tanks are where these systems really shine as they spread oxygen evenly through all water depths. While mechanical systems mix contents better in specific areas, they use more power than diffused systems.

Choosing between diffused and mechanical systems

Tank depth, wastewater characteristics, and energy usage are the foundations of choosing between diffused and mechanical aeration. Diffused systems cut energy use by 30-50% compared to mechanical options, though mechanical systems mix contents better.

Diffused aeration works best in tanks deeper than 8 feet. Shallow tanks usually do better with mechanical systems. Tank shape also matters – floor layouts with diffused aeration mix efficiently, and in-line setups create helpful spiral flow patterns.

Many treatment plants take the best of both worlds. They use mechanical systems where intense mixing is needed and diffused aeration in treatment zones to transfer oxygen efficiently.

Optimizing Aeration Tank Performance for Efficiency

Smart aeration management can cut operational costs in treatment facilities. Aeration alone makes up 40-60% of a plant’s total energy use. These systems have room for major improvements in several areas.

Oxygen transfer efficiency (OTE) and energy use

The transfer rate of oxygen from air to water affects energy consumption directly. Well-designed aeration systems can cut air usage by more than 60% without compromising effluent quality. Fine pore aeration systems deliver 4-7 pounds of oxygen per horsepower-hour. This makes them more energy-efficient than coarse bubble or mechanical options. Systems that adjust aeration based on immediate dissolved oxygen readings can reduce energy use by 15-20%.

Mixing intensity and dead zone prevention

Good mixing stops “dead zones” from forming where treatment fails to work. Studies of flow patterns show a clear link between oxygen distribution and contaminant levels. Mixers placed at strategic points create better circulation patterns. This can improve outlet concentrations of COD, NH4+-N, and TN by about 2%. Deeper tanks with conical bottoms need special mixing systems that follow the tank’s slope to eliminate dead spots.

Sludge buildup and volume reduction strategies

The right sludge volume helps keep treatment working well. Higher mixed liquor suspended solids cuts down excess sludge waste and lowers treatment costs. Smart aeration timing with the best mix of aerated and non-aerated phases saves energy. This approach also changes the microbial community makeup, which can speed up sludge breakdown.

Sludge Management and Equipment Integration

The management of residual sludge after aeration plays a crucial role in treatment plant efficiency. Modern equipment like paddle dryers provides budget-friendly solutions to handle this challenging byproduct.

Paddle dryers for post-aeration sludge drying

Paddle dryers are advanced thermal processing systems that dewater sludge after aeration. The system’s design features horizontal troughs with rotating paddles that mix and move sludge through the drying chamber. A dual heating effect happens through both hollow shafts/paddles and heated chamber walls, which makes the process highly efficient. This design helps turn wet, hard-to-handle sludge into dry, manageable material.

Benefits of integrating paddle dryers in STPs

Sewage treatment plants can gain significant advantages by adding paddle dryers. These systems cut sludge volume by 70-90%, which leads to much lower disposal costs. Dried sludge has high calorific value (8-12 MJ/kg) and works well for energy recovery. The system’s enclosed design also reduces odor emissions and creates a safer workplace.

Pre-treatment and temperature control in sludge drying

The sludge needs proper pre-treatment to remove large particles that might damage the equipment. Biological materials are sensitive to heat, so proper temperature control is essential for optimal drying efficiency. The system typically runs at temperatures between 100-250°C, depending on the heating medium.

Conclusion

Aeration tanks are the life-blood of sewage treatment processes. This piece explores how these vital components make biological treatment easier through oxygen provision. They create environments where beneficial microorganisms thrive and break down harmful pollutants. The activated sludge process depends on well-designed aeration systems that teams manage to keep running smoothly.

Each aeration technology has its own advantages based on operational needs. Fine bubble diffusers work better at transferring oxygen but need more upkeep. Coarse bubble systems mix better and are less likely to clog. Surface aerators show best results in shallow tanks. Subsurface mechanical systems distribute oxygen better in deeper waters. The choice between these options depends on the tank’s geometry, wastewater properties, and energy needs.

Better aeration tank performance cuts operational costs by a lot, especially since aeration uses 40-60% of a plant’s total energy. The right oxygen transfer, proper mixing intensity, and good sludge management help maximize treatment results while using fewer resources.

Without doubt, managing sludge after aeration matters just as much in the treatment process. Paddle dryers are a great solution that reduces sludge volume by 70-90%. They also create opportunities to recover energy from dried materials.

A sewage treatment plant’s success depends on using proper aeration methods. Water management challenges grow as populations and industrial activities expand. Advanced aeration systems will stay at the vanguard of creating eco-friendly water treatment solutions. These essential components protect public health and preserve our water resources for future generations.

Key Takeaways

Understanding the critical role of aeration tanks in sewage treatment helps optimize plant performance and reduce operational costs while ensuring effective wastewater treatment.

• Aeration tanks enable biological treatment by providing oxygen for aerobic bacteria to decompose organic matter, reducing BOD by 70-90% through the activated sludge process.

• Fine bubble diffusers achieve 30-50% energy savings over mechanical systems with superior oxygen transfer efficiency of 5-7% per meter versus 2-4.5% for coarse systems.

• Optimizing aeration performance can reduce total plant energy consumption by 15-20% since aeration accounts for 40-60% of treatment facility energy costs.

• Proper mixing prevents dead zones and improves treatment efficiency, while strategic sludge management reduces disposal costs and creates energy recovery opportunities.

• Integrating paddle dryers post-aeration reduces sludge volume by 70-90% and transforms waste into valuable biomass with 8-12 MJ/kg calorific value for energy applications.

Effective aeration tank design and operation forms the foundation of sustainable wastewater treatment, directly impacting both environmental protection and operational economics in modern sewage treatment facilities.

Frequently Asked Questions

Q1. What is the main function of an aeration tank in sewage treatment?

An aeration tank provides oxygen to support the growth of beneficial bacteria that break down organic pollutants in wastewater. This process, known as biological treatment, is crucial for reducing contaminants and producing clean effluent.

Q2. How does aeration contribute to the efficiency of sewage treatment plants?

Aeration plays a vital role in sewage treatment by facilitating the activated sludge process. It enables aerobic bacteria to decompose organic matter, significantly reducing the biological oxygen demand (BOD) of wastewater by 70-90%.

Q3. What are the different types of aeration systems used in wastewater treatment?

There are two main types of aeration systems: diffused and mechanical. Diffused systems include fine and coarse bubble diffusers, while mechanical systems can be surface or subsurface. Each type has its advantages depending on factors like tank depth and energy efficiency requirements.

Q4. How can aeration tank performance be optimized?

Optimizing aeration tank performance involves improving oxygen transfer efficiency, ensuring proper mixing to prevent dead zones, and implementing effective sludge management strategies. These measures can significantly reduce energy consumption and operational costs.

Q5. What role do paddle dryers play in sludge management after aeration?

Paddle dryers are used for post-aeration sludge drying. They can reduce sludge volume by 70-90%, decreasing disposal costs. The dried sludge can also be used for energy recovery applications due to its high calorific value.