Wastewater treatment is no longer a secondary environmental concern—it is one of the most critical challenges of our time. With rapid urbanization, industrial expansion, and rising environmental regulations, the demand for efficient, sustainable, and compact wastewater treatment systems is higher than ever.

One of the most advanced and widely adopted technologies in modern wastewater treatment is the Sequencing Batch Reactor (SBR). Unlike conventional continuous-flow systems, the SBR operates in time-based cycles, treating wastewater in a single tank through different phases—filling, aeration, settling, decanting, and idle. This cyclic operation provides flexibility, superior treatment efficiency, and compliance with stringent discharge norms.

What is a Sequencing Batch Reactor (SBR)?

A Sequencing Batch Reactor (SBR) is an activated sludge process-based wastewater treatment system that operates in batch cycles instead of continuous flow.

Unlike conventional ASP (Activated Sludge Process) or MBBR (Moving Bed Biofilm Reactor), the SBR combines all treatment stages into one reactor tank, eliminating the need for separate primary clarifiers, aeration tanks, and secondary clarifiers.

Key advantages of SBR:

Compact design with fewer tanks.

Ability to handle fluctuating loads.

High-quality effluent suitable for reuse.

Simple automation with programmable logic controllers (PLC).

The SBR Process: Step-by-Step

The operation of an SBR can be divided into five distinct phases:

1. Fill Phase

Wastewater enters the reactor tank.

Can be static fill (no aeration) or mixed fill (with aeration).

Microorganisms come in contact with fresh wastewater.

2. React (Aeration) Phase

Air is supplied through blowers and diffusers.

Microorganisms oxidize organic matter, reducing BOD, COD, and ammonia.

Nitrification and denitrification processes occur depending on oxygen supply.

3. Settle Phase

Aeration stops, and biomass (sludge) settles at the bottom.

Clear treated water separates from solids.

No mechanical clarifier is required.

4. Decant Phase

The treated supernatant is decanted using a floating decanter system.

Effluent is of high quality, typically meeting CPCB/NGT norms for discharge.

5. Idle Phase

Optional phase used for sludge wasting, system balancing, or standby.

Design Considerations for SBR

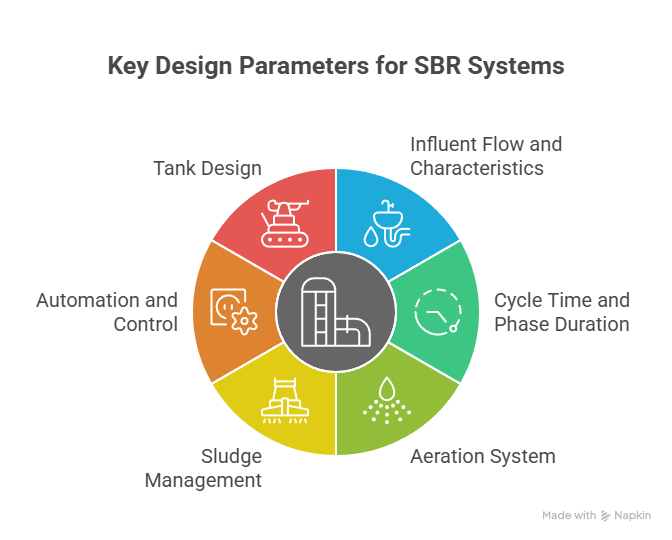

Designing an efficient SBR requires careful planning. Some critical design parameters include:

Influent Flow and Characteristics

BOD, COD, TSS, Ammonia, TN, TP levels.

Industrial wastewater requires pre-treatment.

Cycle Time and Phase Duration

Typically 4–8 hours per cycle.

Adjusted based on influent load and effluent requirements.

Aeration System

Fine bubble diffusers or surface aerators.

Oxygen transfer efficiency determines energy consumption.

Sludge Management

Wasting strategy must balance MLSS levels.

Sludge age (SRT) impacts nutrient removal efficiency.

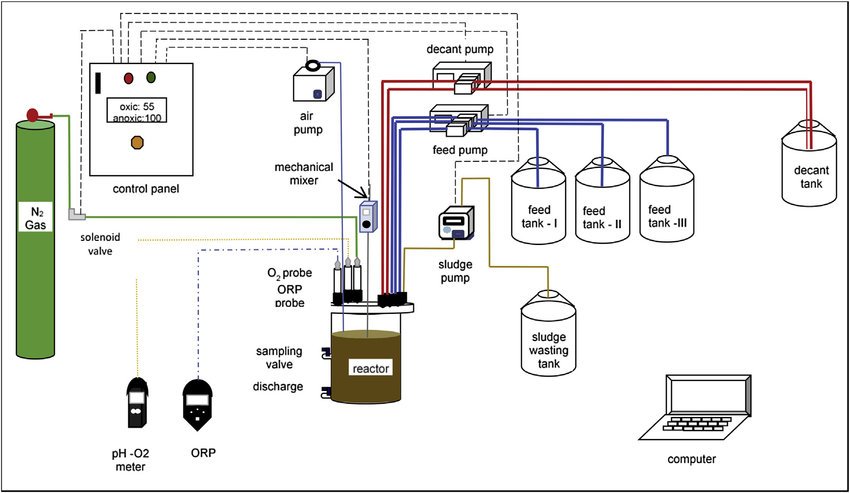

Automation and Control

PLC/SCADA systems ensure accuracy.

Online sensors for DO, pH, ORP, and ammonia improve stability.

Tank Design

Typically cylindrical or rectangular tanks in RCC or FRP.

Depth: 4–6 m, depending on aeration requirements.

Applications of SBR in Wastewater Treatment

The versatility of SBRs makes them suitable for a wide range of applications:

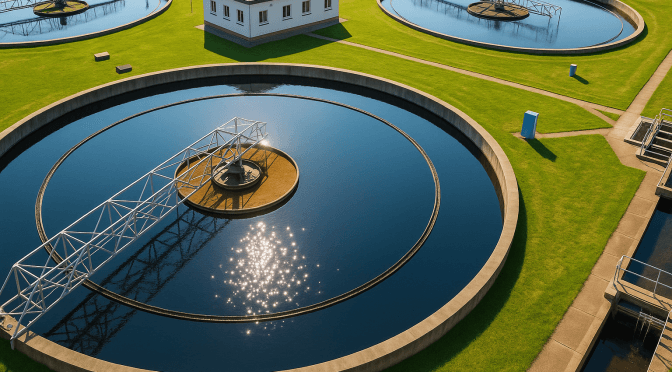

1. Municipal Wastewater Treatment

Used in cities and towns with fluctuating sewage flows.

Compact footprint makes it suitable for urban areas.

2. Industrial Wastewater Treatment

Common in food processing, pharmaceuticals, textiles, and chemical industries.

Can be modified for nutrient removal and high organic loads.

3. Decentralized and Packaged STPs

Perfect for residential complexes, IT parks, hospitals, hotels, and resorts.

Prefabricated modular units are easy to install and relocate.

4. Reuse Applications

Treated water from SBR can be reused for:

Gardening & landscaping.

Toilet flushing.

Cooling tower make-up.

Construction activities.

Advantages of SBR Technology

High effluent quality (BOD < 10 mg/L, TSS < 10 mg/L).

Flexibility to handle peak loads and varying influent.

Compact & modular design, reducing land cost.

Energy-efficient when optimized with IoT sensors.

Compliance with CPCB/NGT discharge norms.

Scalable from 10 KLD to several MLD.

Limitations of SBR

Requires skilled operators.

Sensitive to toxic shock loads (industrial wastewater).

Electrical/mechanical reliability of decanters and blowers is critical.

Sludge management requires proper planning.

SUSBIO and the SUSBIO SBR

At Sustainable Biosolutions Pvt. Ltd. (SUSBIO), we are committed to redefining the future of wastewater management through innovation, sustainability, and advanced engineering. Over the years, our team of wastewater experts and process engineers has designed solutions that are not only technically superior but also practically efficient, making wastewater treatment accessible, affordable, and reliable for a wide range of applications.

Our flagship innovation, the SUSBIO SBR (Sequencing Batch Reactor), is an advanced wastewater treatment system engineered to deliver consistent performance, regulatory compliance, and long-term sustainability. Unlike traditional sewage treatment plants that rely on multiple tanks and complex layouts, the SUSBIO SBR integrates the entire process into compact prefabricated FRP tanks, enhanced with IoT-enabled automation for real-time monitoring and control.

Why Choose SUSBIO SBR?

1. Compact, Prefabricated Design

The SUSBIO SBR is built using high-quality Fiber Reinforced Plastic (FRP) tanks that are lightweight, durable, and corrosion-resistant. Unlike RCC-based conventional plants that take months to construct, our prefabricated modular systems can be installed and commissioned in a matter of weeks.

Space efficiency: Requires up to 40% less space compared to conventional STPs.

Durability: Comes with a 10+ year warranty on the tank structure, ensuring long life and minimal maintenance.

Flexibility: Modular design allows easy capacity expansion as sewage load increases.

2. Dual-Phase Treatment

The SUSBIO SBR process is optimized to achieve superior BOD and COD reduction, as well as effective nutrient removal (Nitrogen and Phosphorus).

Advanced sequencing cycles ensure that each batch of wastewater is treated with precision.

Capable of meeting stringent CPCB/NGT discharge norms with effluent quality as low as BOD ≤ 10 mg/L and TSS ≤ 10 mg/L.

Treated water is safe for reuse in landscaping, flushing, and industrial utilities, supporting sustainable water management.

3. IoT Integration for Smart Operation

One of the standout features of the SUSBIO SBR is its IoT-enabled monitoring system. Using a centralized dashboard, plant operators can:

Track real-time parameters like DO, pH, ORP, ammonia, and MLSS.

Receive automated alerts and alarms in case of deviations.

Access remote performance data, making it easier to maintain compliance without manual supervision.

This smart integration reduces the dependency on skilled operators while ensuring maximum uptime and reliability.

4. Energy and OPEX Savings

Energy efficiency is at the core of every SUSBIO design. The SUSBIO SBR is engineered to reduce energy consumption by 65–70% compared to traditional continuous systems.

Optimized aeration control and intelligent cycle programming reduce blower run-time.

Low sludge generation minimizes sludge handling and disposal costs.

Overall, O&M costs are reduced to ₹8–12 per KL of treated water, making it one of the most cost-effective wastewater treatment solutions available.

5. Versatility Across Applications

The SUSBIO SBR is highly adaptable and has been successfully deployed across a wide spectrum of sectors:

Residential complexes & apartments – ensuring reliable sewage management for growing urban populations.

Luxury villas & resorts – where odor-free, noise-free, and compact systems are essential.

Hospitals & healthcare facilities – where consistent effluent quality is critical to avoid environmental health risks.

IT parks & commercial complexes – handling fluctuating wastewater loads with ease.

Industries – including food & beverage, textiles, and pharmaceuticals, with modifications for specific influent characteristics.

Proven Track Record

With dozens of successful installations across India and Sri Lanka, the SUSBIO SBR has earned the trust of developers, industrial groups, municipalities, and institutions. Each installation stands as a testament to our engineering expertise, commitment to sustainability, and dedication to compliance.

By combining advanced process design, durable prefabricated tanks, IoT-driven monitoring, and cost efficiency, SUSBIO SBR is shaping the future of wastewater treatment—making it smarter, faster, and more sustainable.

Conclusion

The Sequencing Batch Reactor (SBR) has emerged as a game-changer in wastewater treatment, offering flexibility, efficiency, and compactness. Its unique cyclic process eliminates the need for multiple tanks, reduces land usage, and ensures stringent compliance with environmental norms.

For municipalities, industries, and residential complexes, SBR provides a sustainable and future-ready solution to wastewater challenges.

At SUSBIO, our SUSBIO SBR systems go a step further by offering prefabricated, IoT-enabled, and energy-efficient reactors that deliver unmatched reliability and performance. Whether it’s an apartment complex, industrial facility, or smart city project, SUSBIO SBR ensures clean water, reduced operational costs, and long-term sustainability.

Frequently Asked Questions

Q1. How is SBR different from MBBR or MBR?

SBR operates in batch cycles in a single tank, while MBBR uses biofilm carriers in continuous flow, and MBR integrates membranes for ultra-filtration. SBR offers simplicity and flexibility, making it cost-effective for many projects.

Q2. What is the typical effluent quality from an SBR?

A well-designed SBR achieves:

BOD < 10 mg/L

COD < 30 mg/L

TSS < 10 mg/L

Ammonia-N < 5 mg/L

Q3. Can SBR handle industrial wastewater?

Yes, but it depends on the type of industry. Pre-treatment (e.g., oil & grease trap, equalization tank, pH adjustment) may be required.

Q4. What is the O&M cost of an SBR plant?

O&M cost typically ranges from ₹8–15 per KL of treated water, depending on plant size, energy efficiency, and automation level.

Q5. Why is SUSBIO SBR considered better than conventional systems?

SUSBIO SBR integrates prefabricated FRP design, IoT monitoring, and advanced process control, ensuring ease of operation, compliance, and cost savings.