The right STP selection for labor camps plays a vital role in construction projects that employ 100 to 200 workers during their 4 to 5 year timeline. Project managers face a major challenge as each worker needs about 45 liters of water daily to manage sewage efficiently.

Project teams used to transport domestic sewage through vacuum tankers, which proved both time-consuming and expensive. Modern containerized sewage treatment plants now offer a more practical approach. These systems pack primary treatment, biological treatment, settling, and tertiary treatment into one container based on capacity needs. On top of that, these adaptable solutions need minimal space and fit perfectly in confined areas.

A proper labor camp’s STP brings benefits beyond just convenience. To name just one example, MBR technology uses advanced filtration membranes with 40-100 nanometer pore sizes that boost filtration accuracy 500 times more than regular filters. This approach cuts down water consumption and boosts construction operations’ sustainability. SUSBIO ECOTREAT has proven itself as India’s most advanced packaged STP—a future-ready solution that delivers reliable sewage treatment.

This piece explores why labor camps need their own STPs. You’ll learn the most important factors to pick the right system and ways to save costs through water reuse applications.

Why Labor Camps Need a Dedicated STP in 2025

Labor camps in the UAE face major problems with sewage management. Many facilities generate massive volumes of waste that overwhelm the available infrastructure. The industrial area of Al Quoz, which houses hundreds of labor camps, generates about 300,000 cubic meters of sewage wastewater daily. These overwhelming numbers show why dedicated sewage treatment solutions are no longer optional but necessary.

Rising sewage volumes and lack of municipal connection

Most labor camps lack direct connections to municipal sewage systems and must rely on septic tanks. Al Quoz houses nearly 150,000 people, and its inadequate sewage infrastructure leads to overflowing tanks and sewage flooding on nearby roads. The Middle East’s rapid urban growth has made domestic wastewater management even more challenging. The gap between sewage generation and available infrastructure keeps growing, especially in industrial zones where construction workers live.

Tankering costs and environmental concerns

Hiring sewage tankers, the traditional solution, now creates more problems:

- Tankers wait 6-7 hours at treatment plants

- Companies charge Dh1500 to Dh2000 per trip

- Dubai’s Al Aweer plant handles about 3,000 trucks with untreated sewage daily

These logistics challenges often result in tanker drivers illegally dumping sewage into storm drains, which eventually pollutes beaches. Labor camp residents get sick from sewage exposure, with clinics treating 5-6 sick workers daily. The environmental damage goes beyond nearby areas, as untreated sewage threatens groundwater and marine ecosystems.

STP for labor camp as a long-term solution

On-site sewage treatment plants offer major benefits for labor camps, despite the upfront costs. These systems process sewage immediately without tankering delays and work independently from municipal infrastructure. SUSBIO ECOTREAT, India’s most advanced packaged STP, provides innovative solutions that fit well in space-limited sites.

Dubai Municipality recognizes these issues and has tightened regulations. Fines against camp owners who fail to maintain hygiene have jumped from Dh1,000 to Dh10,000. Companies that install dedicated STPs report lower water bills, better camp hygiene, and better alignment with regional sustainability goals.

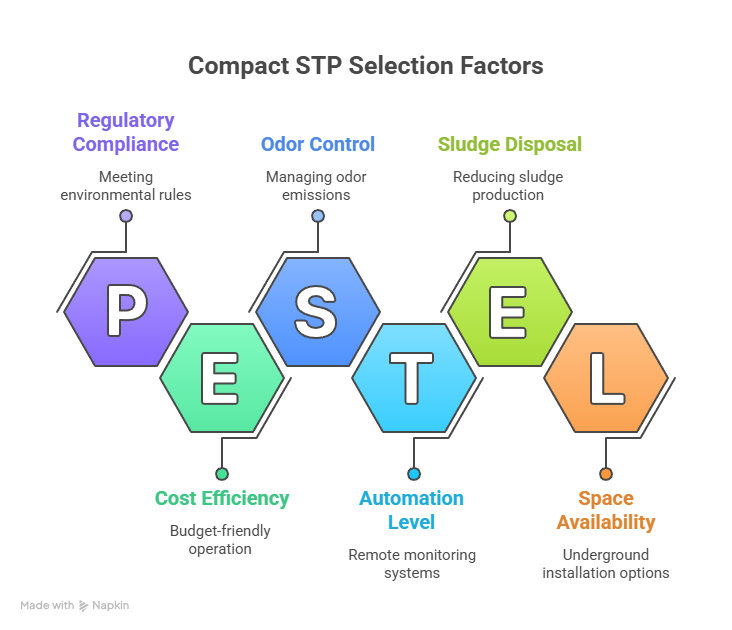

Key Factors to Consider When Choosing a Compact STP

Picking the right STP for a labor camp needs you to think about several factors. This ensures the best performance, meets regulations, and stays budget-friendly throughout the project.

1. Daily sewage load and peak usage estimation

The right calculation of sewage flow builds the foundation for proper STP sizing. Labor camp workers typically generate about 45 liters of sewage per person each day. A camp with 100-200 workers produces 4,500-9,000 liters daily. You’ll need to add a peak flow factor of 2.0-3.0 to handle usage spikes. A safety margin of 10-15% helps deal with infiltration or unexpected flow changes. The wrong size can cause problems – too small leads to overload, while too big wastes money and resources.

2. Space availability and underground installation options

Space limits often shape your STP choice for labor camps. Containerized STPs solve this cleverly by fitting complete treatment systems in standard 20ft or 40ft containers. You can also save space by installing them underground, usually beneath parking lots or recreational areas. Before going underground, you need a full picture of soil and groundwater conditions to guarantee structural stability.

3. Power supply compatibility and energy efficiency

Power availability affects STP selection by a lot. New compact STPs like SUSBIO ECOTREAT work with different power options, including 85-265V AC or 16.8-31.2V DC. Some new systems work without electricity – perfect for remote spots with unreliable power. Sites with stable power should look for energy-smart designs that use less power during quiet periods.

4. Sludge generation and disposal frequency

Sludge management creates ongoing challenges for camp operators. Modern STPs can cut sludge production by 50-70% compared to older systems. Your system needs enough sludge storage – usually seven days’ worth – to make disposal easier. Dewatering features help reduce volume and cut handling costs.

5. Odor control and environmental compliance

Camps must manage odor emissions, mainly hydrogen sulfide (5-15 ppm) and ammonia (50-150 ppm), especially near homes. Good STPs control odors through enclosed designs, chemical neutralization, or biological filtration. Meeting local environmental rules isn’t optional and might need specific discharge permits.

6. Ease of operation and automation level

Labor camps rarely have skilled operators, so automation becomes crucial. Modern STPs come with different automation levels, from simple timers to advanced SCADA systems that allow remote monitoring. The best solution needs minimal human input while working reliably throughout the project.

Comparing STP Technologies for Labor Camps

Understanding the key differences between STP technologies is significant to make the best decisions about sewage management solutions for construction sites.

Packaged STP vs Modular STP: Which suits your site?

Packaged STPs come as complete, pre-engineered units that need minimal civil work. On the other hand, modular STPs provide scalability through interconnected treatment modules. Packaged systems take about 2-4 weeks to install, which makes them perfect for temporary labor camps. The BOO-BOT deployment model at Dubai Industrial City shows how modular solutions cut sewage management costs by 70% without any upfront capital investment.

MBR vs MBBR vs SBR: Performance and footprint

Each technology has its unique advantages:

- MBR (Membrane Bioreactor): Delivers superior effluent quality (BOD/SS <5 mg/l) and works great for water reuse but costs AED 2.57-5.51/m³ to operate.

- MBBR (Moving Bed Biofilm Reactor): Manages shock loads well with reasonable land needs and operating costs of AED 1.10-2.20/m³.

- SBR (Sequencing Batch Reactor): Reaches BOD/SS <10 mg/l with flexible operation but requires precise control systems.

SUSBIO ECOTREAT: World’s most advanced packaged STP

SUSBIO ECOTREAT is an ideal sewage treatment technology for labor camps in the UAE, Saudi Arabia, and Muscat due to its compact design, low maintenance, and high efficiency under extreme climatic conditions. Engineered with advanced biological treatment and FRP-based prefabricated construction, it ensures durability, corrosion resistance, and quick installation, making it perfectly suited for remote or temporary labor accommodations. The system delivers consistent treated water quality that meets Gulf environmental standards, allowing safe reuse for landscaping or flushing, which supports regional water conservation goals. With its plug-and-play operation, minimal manpower requirement, and energy-efficient performance, SUSBIO ECOTREAT offers a reliable, sustainable, and cost-effective wastewater treatment solution tailored to the needs of labor camps across the Middle East.

Case example: Labor-STP deployment in UAE

Yas Island Worker Camp successfully uses MBBR technology to process 3,000m³/day and reuses water for irrigation. Hans Esser Real Estate’s 2024 MBR installation shows up to 80% reduction in water bills and better camp hygiene standards.

Reuse Applications and Cost Savings from Treated Water

Treated water from labor camp STPs is a valuable resource, not waste. It helps save costs and benefits the environment.

Toilet flushing and gardening reuse

People use 30-40% of their total water just to flush toilets. This makes it perfect to reuse treated water. SUSBIO ECOTREAT, India’s most advanced packaged STP, makes shared water systems possible. The treated sewage serves non-potable needs. The system needs 1.0 ppm chlorine content at flushing points to stay safe. Clear labels help tell treated water pipes from drinking water supplies. The treated water’s nutrients are great for gardens. They act as mild fertilizers and save fresh water.

Construction and cooling tower applications

Labor camp STPs provide treated water that works well in construction. Mixing concrete needs about 150 liters per cubic meter. The water also helps control dust and compact soil. UAE facilities save money by recycling water – one site saved AED 340,000 each year. Cooling towers also work better with treated water. Studies show they can run almost twice as long with treated sewage, which cuts water use by 27%.

STP operating procedure for water reuse compliance

The system needs proper care of tertiary treatment equipment to work safely. Regular tests check BOD, TSS, and coliforms to meet standards. Storage tanks must have clear labels, and the core team needs proper safety training. SUSBIO ECOTREAT systems pay for themselves in 18-24 months, especially in busy labor camps.

Conclusion

The right STP choice for your labor camp can revolutionize project sustainability, worker welfare, and financial performance. Traditional sewage management methods don’t deal very well with modern needs, while containerized solutions provide budget-friendly alternatives for construction sites.

Rising tankering service costs and environmental concerns have made dedicated on-site treatment systems a necessity. Project managers can pick suitable technologies by thinking over factors like daily sewage load, space constraints, and power requirements. The comparison between technologies such as MBR, MBBR, and SBR helps make informed decisions based on treatment quality, footprint, and operational costs.

SUSBIO ECOTREAT has emerged as India’s most advanced packaged STP. This future-ready solution offers dual-treatment processes with remarkable energy efficiency. The system delivers exceptional performance with a compact footprint, making it perfect for space-constrained labor camps.

The financial advantages of proper sewage treatment go beyond just compliance. Water reuse applications like toilet flushing, gardening, construction activities, and cooling towers lead to significant cost savings. What seems like an expense now becomes an investment with payback periods of just 18-24 months.

Construction projects today face strict environmental scrutiny and water shortage challenges. The appropriate STP technology has become essential rather than optional. A well-chosen system handles immediate sewage management needs and supports broader sustainability goals while providing measurable returns throughout the project lifecycle.

Key Takeaways

Selecting the right compact STP for labor camps requires strategic planning to address rising sewage volumes, reduce costs, and ensure environmental compliance in 2025.

- Calculate sewage load accurately: Plan for 45 liters per worker daily with 2-3x peak flow factor and 10-15% safety margin to avoid system overload.

- Choose technology based on site needs: MBR offers superior water quality for reuse, MBBR handles shock loads well, while SBR provides flexible operation.

- Prioritize space-efficient solutions: Containerized STPs fit in 20ft/40ft containers, while underground installation maximizes available space utilization.

- Maximize water reuse for cost savings: Treated water for toilet flushing, construction, and cooling towers can reduce water bills by up to 80% with 18-24 month payback periods.

- Consider automation levels: Labor camps need automated systems with minimal manual intervention to ensure reliable performance without skilled operators.

Modern compact STPs like SUSBIO ECOTREAT transform sewage management from an operational burden into a sustainable investment, delivering both environmental compliance and significant cost reductions for construction projects.

Frequently Asked Questions

Q1. How do I determine the appropriate size for a labor camp STP?

To size an STP for a labor camp, calculate 45 liters of sewage per worker daily. Apply a 2-3x peak flow factor and add a 10-15% safety margin. For example, a 200-worker camp would generate about 9,000 liters daily, requiring an STP capacity of at least 11,700-13,500 liters per day.

Q2. What are the main STP technologies suitable for labor camps?

The main STP technologies for labor camps are MBR (Membrane Bioreactor), MBBR (Moving Bed Biofilm Reactor), and SBR (Sequencing Batch Reactor). MBR produces high-quality effluent ideal for water reuse, MBBR handles fluctuating loads well, and SBR offers flexible operation with precise control.

Q3. How can treated water from an STP be reused in a labor camp?

Treated water from an STP can be reused for toilet flushing, gardening, construction activities like concrete mixing and dust suppression, and in cooling towers. This reuse can significantly reduce freshwater consumption and lower water bills by up to 80%.

Q4. What are the key factors to consider when choosing a compact STP for a labor camp?

Key factors include daily sewage load, space availability, power supply compatibility, sludge generation and disposal, odor control, environmental compliance, and the level of automation. It’s crucial to select a system that matches the specific needs of your labor camp and project requirements.

Q5. How long does it typically take for an STP investment to pay off in a labor camp setting?

In a labor camp setting, the investment in an STP typically pays off within 18-24 months. This quick return on investment is achieved through significant reductions in water bills, tankering costs, and improved camp hygiene standards.