Effluent Treatment Plants (ETPs) are essential infrastructure for industries that generate wastewater. By treating effluents from various industrial processes, ETPs ensure that harmful pollutants including those contributing to domestic sewage water pollution are removed before discharge into the environment, helping to mitigate the adverse effects of industrial waste on ecosystems and human health. This article explores what ETPs are, their role in wastewater management, and their importance in achieving sustainable industrial growth.

What are Effluent Treatment Plants?

An Effluent Treatment Plant (ETP) or wastewater treatment plant is a facility that processes wastewater from industries to reduce or eliminate pollutants, contaminants, and hazardous materials before it is discharged into the environment. Industries such as textiles, chemicals, pharmaceuticals, food processing, and oil and gas produce wastewater as a byproduct, which, if untreated, can have severe ecological and health consequences. ETP plants employ a series of physical, chemical, biological, and filtration processes to treat this water and make it safe for reuse or discharge. Implementing an effective wastewater treatment model ensures that the ETP process is efficient, sustainable, and compliant with environmental regulations, helping industries manage their wastewater responsibly.

Key Components and Processes in an Effluent Treatment Plant

Primary Treatment

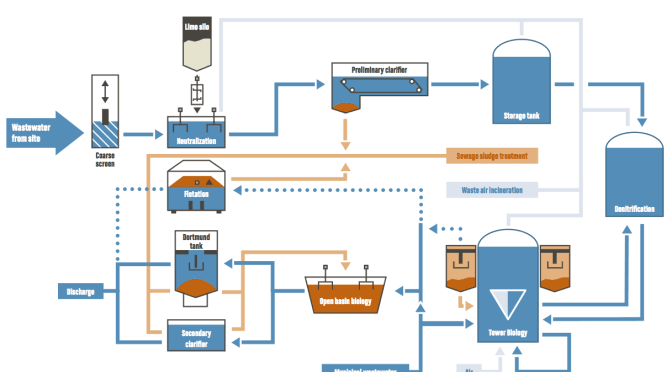

Primary wastewater treatment involves removing larger solids, oils, and greases from the wastewater. This stage includes screening, grit removal, and sedimentation. Clarifiers and settling tanks are used in this phase of the wastewater treatment process, where coarse materials are removed. An equalization tank may also be employed to balance the flow and composition of the incoming wastewater.Secondary Treatment

Secondary wastewater treatment targets dissolved organic matter through biological processes. The activated sludge process, biofilters, and aerated lagoons are some of the methods used to promote microbial growth, breaking down organic pollutants in the water. This stage often involves an aeration system, which can include surface aerators or a diffused aeration system. The process results in the formation of biological floc, which helps in removing contaminants. Trickling filters can also be used as an alternative to the activated sludge process in some cases.Tertiary Treatment

Tertiary wastewater treatment is an advanced process that further purifies the effluent through additional filtration, chemical treatment, and disinfection. This stage often includes processes like reverse osmosis, ion exchange, and activated carbon filtering, which help remove residual pollutants and pathogens. Membrane processes and UV disinfection are also commonly used in this stage, ensuring the treated water meets environmental standards and discharge standards.Sludge Management

Sludge generated from the treatment process is collected, treated, and disposed of responsibly. Some plants also use sludge treatment methods like anaerobic digestion to produce biogas, contributing to energy efficiency and reducing operating costs.

The Role and Importance of Effluent Treatment Plants

1. Protecting Public Health

ETPs play a critical role in protecting public health by removing toxic and harmful chemicals from wastewater. Untreated industrial effluents often contain hazardous chemicals and pathogens that can contaminate drinking water sources and pose risks to human health. Proper treatment ensures that these contaminants are neutralized before the water is either reused or released.

2. Safeguarding Ecosystems

Industrial wastewater, if released untreated, can destroy aquatic life, soil health, and vegetation. ETPs help protect rivers, lakes, and coastal ecosystems by reducing the pollution load in water bodies, thus maintaining ecological balance and preserving biodiversity. This aspect of environmental protection is crucial for long-term sustainability.

3. Legal Compliance and Avoidance of Penalties

Regulatory bodies worldwide mandate wastewater treatment standards to control pollution. Non-compliance with these regulations can lead to hefty fines, legal action, and even facility shutdowns. ETPs help industries adhere to these standards, thus ensuring regulatory compliance and avoiding penalties. This is particularly important for industries dealing with complex waste streams, such as winery wastewater.

4. Promoting Sustainable Industrial Growth

With the growing emphasis on environmental conservation, industries are increasingly encouraged to adopt sustainable practices. ETPs enable companies to manage their waste responsibly, reducing their environmental footprint. This not only supports sustainable growth but also enhances a company’s reputation, making it more attractive to environmentally conscious consumers and investors. These sustainable practices are especially crucial in industrial wastewater treatment, where responsible water management plays a key role in reducing environmental impact.

5. Supporting Water Reuse and Conservation

ETPs make it possible to recycle treated effluent for various industrial applications, such as cooling systems, irrigation, and boiler feed. By reducing freshwater intake, industries can conserve water resources, a critical benefit, especially in water-scarce regions. Reusing treated effluent also contributes to cost savings, making operations more economical. Some advanced systems even aim for zero liquid discharge, maximizing water reuse and minimizing environmental impact.

Conclusion: Why Effluent Treatment Plants are Essential

Effluent Treatment Plants are indispensable for industries aiming to minimize their environmental impact and promote sustainability. By efficiently removing pollutants from industrial wastewater, ETPs protect public health, preserve natural ecosystems, and ensure compliance with environmental regulations. Their ability to enable water reuse and resource conservation further supports industries in building eco-friendly practices. The sewage treatment process within these systems plays a crucial role in achieving these objectives, ensuring that wastewater is treated effectively for reuse and reducing the strain on natural water sources, making them a vital component of industrial water treatment solutions.

In today’s context of heightened environmental awareness and regulatory oversight, installing a robust ETP is no longer optional but a critical component of responsible industrial operations. As industries continue to grow, so does the demand for effective wastewater management solutions, and ETPs stand at the forefront of this essential shift towards cleaner and more sustainable industrial processes. By investing in modern ETPs, industries can pave the way for a healthier, safer environment while also supporting long-term economic viability. These advanced systems also provide effective liquid waste treatment, ensuring that industrial wastewater is properly treated to meet environmental standards and minimize the impact on natural resources, all through efficient chemical wastewater treatment.

Frequently Asked Questions

Q1. How can wastewater treatment plants reduce operational costs in 2026?

Wastewater treatment plants can reduce operational costs by implementing equalization tanks, automated sludge dewatering systems, IoT-based monitoring, advanced coagulants, and preventive maintenance tools. These solutions lower energy consumption, reduce chemical usage, and minimize unplanned downtime.

Q2. What is the most cost-effective upgrade for an existing sewage treatment plant?

One of the most cost-effective upgrades for an existing sewage treatment plant (STP) is installing equalization tanks and real-time IoT monitoring systems. These improve load balancing, prevent shock loads, optimize aeration, and reduce overall treatment costs without major infrastructure expansion.

Q3. How does IoT monitoring improve wastewater treatment efficiency?

IoT monitoring systems provide real-time tracking of BOD, COD, TSS, pH, and flow rates. This enables predictive maintenance, early fault detection, optimized energy usage, and better compliance with environmental discharge norms.

Q4. Which wastewater treatment technology saves the most space and energy?

Compact MBBR (Moving Bed Biofilm Reactor) systems are among the most space-efficient and energy-saving wastewater treatment technologies. They deliver high treatment efficiency in up to 70% less space compared to conventional activated sludge processes.

Q5. Why is preventive maintenance important in wastewater treatment plants?

Preventive maintenance reduces unexpected breakdowns, extends equipment lifespan, lowers repair costs by up to 40%, and ensures continuous compliance with environmental regulations. It shifts operations from reactive to proactive management.

10 Comments

[…] blog explores the critical role of ETPs, the industries that need them, the processes involved, and why they are indispensable for […]

[…] Effluent Treatment Plants (ETP) play a pivotal role in managing industrial wastewater. With India’s industrial sector expanding rapidly, the need for efficient wastewater management has become a top priority for businesses and environmental agencies alike. Among the leading players in this domain, SUSBIO stands out as the best Effluent Treatment Plant (ETP) manufacturer in India, offering cutting-edge solutions tailored to diverse industries. […]

[…] global economic growth, generates significant volumes of wastewater laden with complex pollutants. Effluent Treatment Plants (ETPs) play a pivotal role in managing and treating pharmaceutical effluents, ensuring compliance with […]

[…] in ensuring environmental sustainability. Two essential technologies for treating wastewater are Effluent Treatment Plants (ETPs) and Sewage Treatment Plants (STPs). While both systems aim to treat wastewater before its […]

[…] Effluent Treatment Plants (ETPs) play a vital role in ensuring that industries comply with environmental regulations by treating wastewater before discharge. With stringent government norms and growing environmental awareness, ETPs are indispensable for sectors that produce significant quantities of wastewater containing harmful contaminants. Below, we explore the top 5 sectors where effluent treatment plants are critical. […]

[…] usage and diverse effluent characteristics, faces significant challenges in managing wastewater. Effluent Treatment Plants (ETPs) play a crucial role in treating and managing this wastewater, ensuring compliance with […]

[…] Effluent treatment plants (ETPs) play a vital role in safeguarding the environment by treating industrial wastewater and ensuring compliance with regulatory standards. Selecting the right ETP manufacturer can significantly impact your business operations, cost efficiency, and sustainability goals. […]

[…] 0 By Akshat Tyagi Latest Blogs November 15, […]

[…] Effluent Treatment Plants (ETPs) play a vital role in managing industrial wastewater, ensuring that harmful pollutants are removed before the water is released back into the environment. India has several leading manufacturers of ETP plants, known for their innovation, reliability, and adherence to environmental standards. Here, we highlight the top 5 ETP plant manufacturers in India, with SUSBIO leading the way. […]

[…] Effluent Treatment Plants (ETPs) play a pivotal role in managing wastewater generated by industrial processes. Designed to treat contaminated water before it is discharged into the environment, ETPs are a cornerstone of sustainable industrial operations. As a leading ETP plant manufacturers in India, SUSBIO is dedicated to providing innovative and efficient solutions for industries striving for environmental compliance. […]