Sewage treatment plants process only about 52% of global sewage, leaving nearly half of the world’s waste untreated. This disparity becomes even more alarming when we compare developed and developing nations—while high-income countries treat approximately 74% of their sewage, developing countries manage to treat a mere 4.2%.

These treatment facilities serve as silent guardians of our water resources, collecting, treating, and discharging wastewater to protect both environmental and public health. Without adequate treatment, sewage would contaminate our ecosystems, threatening the very water sources we depend on. The sewage treatment plant process typically involves multiple stages—from preliminary screening to advanced tertiary treatments—all designed to handle organic and inorganic wastes before releasing water back into the environment.

In this article, we’ll explore what sewage treatment plants are, why they matter, and how they function. We’ll break down the step-by-step processes, examine key components, discuss different types of sewage treatment plants, and investigate how treated water can be reused. By understanding these systems, we can better appreciate their critical role in maintaining a healthy and sustainable environment for all of us.

What is a Sewage Treatment Plant and Why It Matters

Sewage treatment plants (STPs) serve as critical infrastructure in our modern world, processing wastewater to protect both human health and the environment. According to data from the Ministry of Housing and Urban Affairs, India currently has 1,261 STPs with a total capacity of 30,001 Million Liters per Day (MLD) across 31 states and union territories. However, only 56% of this capacity is actually utilized for treating municipal sewage, highlighting a significant gap between available infrastructure and practical implementation.

Definition and Purpose of STPs

A sewage treatment plant is a facility specifically designed to remove contaminants from wastewater, primarily from domestic and industrial sources. The main objective of these plants is to produce clean water (effluent) that can be safely discharged into the environment or reused for various purposes. Through a combination of physical, chemical, and biological processes, STPs transform raw sewage into treated water that meets regulatory standards.

The primary purpose of sewage treatment plants is threefold: to protect public health by removing harmful pathogens and pollutants from wastewater; to safeguard aquatic ecosystems by preventing contamination of rivers, lakes, and oceans; and to enable water reuse, thereby reducing demand on freshwater resources. Furthermore, the Ministry of Environment, Forest and Climate Change has established specific discharge standards through the Environment (Protection) Rules that STPs must adhere to.

Difference Between Sewage and Wastewater Treatment

Although often used interchangeably, sewage and wastewater are not identical concepts. Sewage is actually a subset of wastewater. Wastewater encompasses all used water from households, industries, and stormwater runoff, containing various pollutants beyond human waste. In contrast, sewage specifically refers to wastewater that comes from residential sources such as toilets, sinks, and showers, containing human waste.

Sewage is further categorized into:

- Blackwater: Wastewater specifically from toilets

- Graywater: Wastewater from all domestic sources except toilets

The distinction matters because different types of wastewater require different treatment approaches. For instance, industrial wastewater often contains high levels of chemical and biological pollutants that can overwhelm standard treatment systems, necessitating additional or specialized treatment processes.

Role of STPs in Urban Sanitation

In urban environments, sewage treatment plants play a fundamental role in maintaining sanitation and public health. As urban populations grow, the volume of wastewater generated increases dramatically, making efficient sewage management essential. STPs prevent the spread of waterborne diseases by removing pathogens such as bacteria, viruses, and parasites that could otherwise contaminate drinking water sources.

Additionally, these facilities protect natural water bodies from pollution. Without proper treatment, raw sewage discharged into rivers or oceans would cause severe environmental damage, including oxygen depletion, destruction of aquatic habitats, and widespread ecosystem disruption. The treated effluent from STPs must meet specific standards for parameters including pH, Biochemical Oxygen Demand, Total Suspended Solids, and Fecal Coliform, as notified in the 2017 amendment to the Environment (Protection) Rules.

Under programs like AMRUT and AMRUT 2.0, significant investments have been made in sewerage infrastructure. AMRUT allocated ₹32,456 crore (42% of its budget) to sewerage and septage projects, resulting in 214 completed STPs with a total capacity of 4,174 MLD. Such initiatives demonstrate the recognized importance of sewage treatment in creating sustainable, healthy urban environments.

Step-by-Step Breakdown of the Sewage Treatment Plant Process

The treatment of sewage involves multiple sequential processes, each designed to progressively remove contaminants from wastewater. Modern sewage treatment facilities utilize a combination of physical, chemical, and biological mechanisms to transform raw sewage into environmentally safe water.

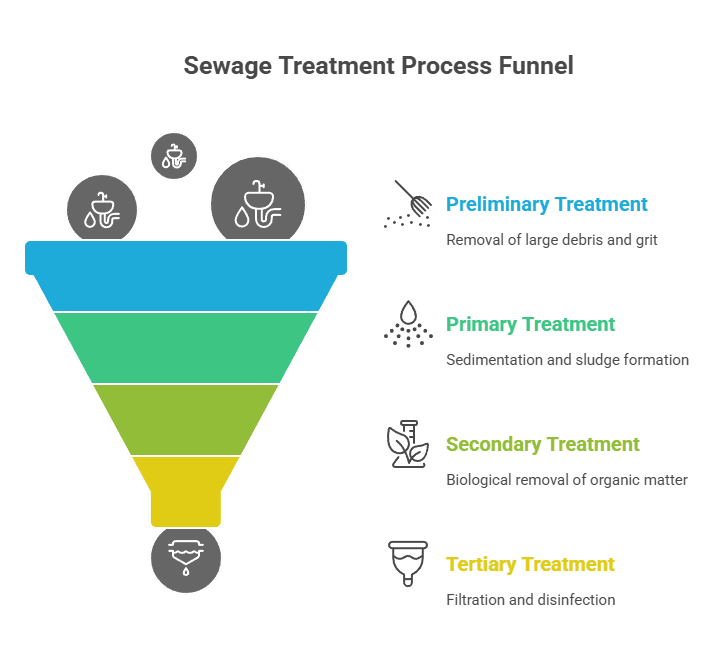

Preliminary Treatment: Screening and Grit Removal

Sewage treatment begins with preliminary treatment, where large, untreatable objects are removed before they cause damage to downstream equipment. This initial stage employs mechanical devices called bar screens that trap debris such as rags, sticks, plastic packets, and other bulky materials. These screens are typically cleaned either manually in smaller plants or by automated mechanisms in larger facilities.

Following screening, the wastewater enters grit chambers where the flow velocity is reduced, allowing heavy particles like sand, gravel, and coffee grounds to settle. This step is crucial as it prevents abrasion and unnecessary wear on pumps and other mechanical equipment. Grit chambers come in various designs including horizontal, aerated, and vortex types. The removal of grit is essential for protecting equipment with closely machined surfaces such as comminutors, fine screens, and heat exchangers.

Primary Treatment: Sedimentation and Sludge Formation

During primary treatment, wastewater passes slowly through sedimentation tanks (also called primary clarifiers) where suspended solids settle to the bottom through gravity, forming primary sludge. These tanks typically provide about two hours of detention time for settling to occur. Simultaneously, oils, grease, and lighter solids float to the surface and are skimmed off.

Mechanically driven scrapers continually move the settled sludge toward a hopper at the bottom of the tank, from where it is pumped out for further treatment. Primary sedimentation tanks can remove approximately 50-70% of suspended solids and 25-40% of the biological oxygen demand (BOD) from sewage. This stage is fundamental in reducing the load on subsequent treatment processes.

Secondary Treatment: Activated Sludge and Biofilm Systems

Secondary treatment primarily focuses on removing dissolved organic matter that escapes primary treatment. The most common method is the activated sludge process, where microbes consume organic impurities as food. In this system, settled sewage is mixed with recycled sludge in an aeration tank where compressed air is injected through diffusers. This oxygen-rich environment promotes the growth of beneficial bacteria that form an active biological suspension called activated sludge.

After approximately six hours in the aeration tank, the mixture flows into a secondary clarifier where the activated sludge settles by gravity. About 30% of this sludge is recirculated back to the aeration tank—a key feature of the activated sludge process—while the remaining 70% undergoes further treatment and disposal. Alternative biological treatment methods include biofilm systems where microorganisms grow attached to media such as rocks, plastic, or ceramic materials.

Tertiary Treatment: Filtration, Disinfection, and Polishing

Tertiary treatment serves as the final stage to further improve water quality before discharge or reuse. This advanced process typically employs filtration through sand beds or membrane processes to remove remaining suspended solids. Various filtration technologies include surface filtration, depth filtration, and membrane filtration.

Disinfection follows filtration to eliminate pathogens. Common methods include chlorination, ultraviolet (UV) radiation, and ozonation. While chlorine has historically been the disinfectant of choice due to its cost-effectiveness, concerns about harmful disinfection by-products have led to increased adoption of UV radiation and ozone.

Additionally, tertiary treatment may involve processes to reduce nutrients such as nitrogen and phosphorus through chemical precipitation or biological nutrient removal. These steps are particularly important when the effluent is discharged into environmentally sensitive water bodies or intended for reuse in applications such as agricultural irrigation or industrial cooling.

Key Components Inside a Sewage Water Treatment Plant

Behind every effective sewage treatment operation lies specialized equipment that handles the various stages of purification. These essential components work together to transform raw sewage into clean, dischargeable water.

Bar Screens, Grit Chambers, and Comminutors

Bar screens serve as the first defense line in sewage treatment plants, intercepting and removing large objects from incoming sewage. These screens consist of parallel bars spaced at predetermined intervals (6-75mm), allowing water to pass while trapping larger solids. Modern facilities typically use mechanically cleaned screens with automated raking systems, though smaller plants may employ manually cleaned screens.

Following screening, grit chambers reduce the wastewater flow velocity, enabling heavier particles like sand, gravel, and coffee grounds to settle. This crucial step prevents abrasion and wear on downstream equipment such as pumps and pipelines. Grit chambers come in several varieties, including horizontal flow, aerated, and vortex types.

Comminutors function differently from screens by grinding large particles into smaller pieces rather than removing them. These devices cut up coarse solids to prevent downstream clogging problems, especially in pumps. Unlike screens, comminutors keep the solids within the flow system, eliminating the need for separate solid waste handling.

Aeration Tanks and Clarifiers

Aeration tanks represent the heart of biological treatment, where oxygen is introduced to support aerobic microorganisms that break down organic pollutants. These tanks use either diffused or mechanical aeration systems to maintain oxygen levels sufficient for bacteria to thrive. The process significantly reduces Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD), making the effluent safer for further treatment.

Clarifiers work alongside aeration tanks to separate solids from liquid through sedimentation. Primary clarifiers remove raw solids and organic matter early in the treatment process, whereas secondary clarifiers handle biologically treated water to remove microbial biomass. As wastewater remains in these tanks, gravity causes suspended solids to settle, forming sludge at the bottom while clarified water rises to the surface for collection.

Sludge Digesters and Dewatering Units

Sludge digesters stabilize organic materials in residual sludge through biological processes. In anaerobic digestion, bacteria decompose organic matter in oxygen-free environments, producing biogas (methane and carbon dioxide) that can be harnessed for energy. This process reduces sludge volume and destroys pathogens, transforming raw sludge into an inoffensive material resembling potting soil.

Dewatering units remove water from digested sludge to reduce its volume for easier transport and disposal. Common technologies include screw presses, belt filter presses, and centrifuges. Modern dewatering equipment can reduce moisture content significantly, transforming sludge from a liquid to a semi-solid or solid state. Properly dewatered sludge contains approximately 30% solids, making it handleable as a solid material rather than a liquid.

Types of Sewage Treatment Plants and Their Applications

The diverse landscape of wastewater management relies on various sewage treatment systems tailored to specific scenarios and needs. Each type offers unique advantages depending on location, population density, and treatment requirements.

Centralized vs Decentralized STPs

Centralized sewage treatment plants serve extensive areas, collecting wastewater from entire cities or large industrial zones through extensive sewer networks. These facilities process thousands of gallons daily at a single location. In contrast, decentralized systems treat wastewater near its source of generation, serving specific communities, buildings, or campuses.

Economic evaluations reveal compelling differences—a study in Sharjah city showed decentralized systems cost 44% less than connecting to existing centralized plants and 23% less than creating new centralized facilities. Decentralized systems require minimal piping infrastructure, reducing capital expenditure and simplifying maintenance. Meanwhile, centralized plants benefit from economies of scale in densely populated urban settings.

Package STPs for Residential and Commercial Use

Package sewage treatment plants offer pre-engineered, self-contained solutions ideal for properties without access to municipal sewers. These prefabricated systems arrive ready for installation, making them perfect for residential complexes, commercial buildings, and small communities.

Commercial STPs function similarly to residential systems but handle greater volumes—capable of serving premises with 200+ employees versus household systems designed for 4-5 people. Advanced package systems like SBR (Sequencing Batch Reactor) models achieve high-quality effluent through controlled treatment cycles. Notably, package STPs bridge the gap between traditional septic systems and centralized facilities, offering higher treatment levels than septic tanks with lower installation costs than connecting to municipal infrastructure.

Industrial STPs and Co-treatment Facilities

Industrial sewage treatment plants address specialized wastewater containing chemicals, heavy metals, and hazardous pollutants. Industries including pharmaceuticals, textiles, food processing, and automobile manufacturing require customized treatment approaches.

Co-treatment facilities represent an emerging solution where industrial wastewater and municipal sewage undergo treatment together in a single plant. This approach enhances treatment efficiency as certain industrial wastewaters provide beneficial co-substrates for microorganisms. Moreover, co-treatment optimizes capacity utilization during fluctuating industrial flow rates. Pre-treatment requirements remain essential to prevent harmful compounds from inhibiting biological processes.

How Treated Sewage Water is Reused and Recycled

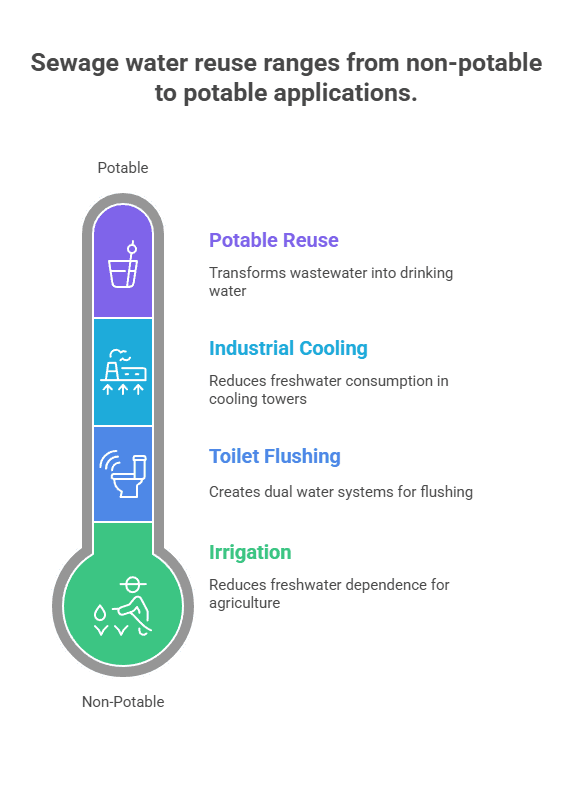

Treated effluent from sewage treatment plants represents a valuable resource rather than waste, offering sustainable alternatives to freshwater consumption. This shift toward water reuse addresses growing scarcity concerns while providing environmental and economic benefits.

Irrigation and Landscaping Applications

Treated sewage water serves as an excellent irrigation source, decreasing dependence on freshwater and reducing aquifer depletion. Agricultural applications range from crop irrigation to landscape maintenance. Studies show farmers increasingly accept using treated wastewater, with a Lebanese study revealing high willingness among farmers to utilize safe treated sewage water.

Golf courses, parks, and public spaces frequently employ treated effluent for irrigation. This practice preserves fresh water reserves, particularly important in drought-prone regions. Indeed, sophisticated tertiary treatment removes nearly all dangerous pathogens and chemicals, making the water safe for gardening purposes.

Toilet Flushing and Industrial Cooling

Non-potable applications extend beyond outdoor uses. Treated sewage water works effectively for toilet flushing systems with proper disinfection—typically maintaining chlorine content around 1.0 ppm at flushing points. This creates a dual water system where conventional networks deliver drinking water alongside secondary networks providing treated wastewater.

Industrial cooling represents another major application. Using treated sewage effluent (TSE) as cooling tower makeup water can reduce freshwater consumption substantially. A pilot study demonstrated that cooling tower cycles of concentration could almost double (from 2 to 3.5) with TSE as makeup water, resulting in 27% reduction in water demand and annual savings of 16,501 m³ for a 1,200-ton AC plant.

Potable Reuse with Advanced Treatment

Potable water reuse transforms treated wastewater into drinking water through advanced purification. Two approaches exist: indirect potable reuse utilizing environmental buffers like lakes or aquifers before drinking water treatment, and direct potable reuse involving immediate distribution without environmental buffers.

Projects like Orange County’s Groundwater Replenishment System demonstrate successful implementation, producing 100 million gallons daily of purified water—enough for 850,000 customers—using microfiltration, reverse osmosis, and ultraviolet light with hydrogen peroxide. These systems consistently meet or exceed all public health standards.

Conclusion

Sewage treatment plants stand as unsung heroes in our modern infrastructure, quietly performing the essential task of transforming harmful waste into safe, reusable water. Throughout this article, we’ve explored the comprehensive process that occurs within these facilities, from preliminary screening to advanced tertiary treatments. Undoubtedly, these systems play a critical role in safeguarding both public health and environmental integrity.

The stark contrast between developed nations treating 74% of their sewage and developing countries managing just 4.2% highlights the global challenge we face. Additionally, even with existing infrastructure, utilization gaps persist—as evidenced by India’s 56% utilization rate of available treatment capacity.

Each component within an STP serves a specific purpose in the purification journey. Bar screens and grit chambers protect downstream equipment, while aeration tanks and clarifiers facilitate the biological breakdown of contaminants. Subsequently, sludge digesters and dewatering units handle the solid waste byproducts efficiently.

The versatility of sewage treatment extends to various configurations adapted to specific needs. Centralized systems serve entire communities, whereas decentralized options provide targeted solutions for residential complexes or commercial establishments. Consequently, this flexibility allows for effective wastewater management across diverse settings.

Perhaps most significantly, treated sewage water represents a valuable resource rather than mere waste. Its applications range from irrigation and landscaping to toilet flushing and industrial cooling. Advanced treatment can even transform wastewater into potable water, therefore addressing water scarcity challenges while promoting sustainability.

As we face increasing water stress globally, the importance of efficient sewage treatment and water recycling becomes paramount. These technologies not only protect our freshwater resources but also offer economic benefits through reduced water consumption. The future of water management depends on our willingness to embrace these systems, close utilization gaps, and expand treatment infrastructure, especially in regions currently lacking adequate facilities.

Key Takeaways

Understanding sewage treatment plants reveals critical infrastructure that transforms waste into valuable resources while protecting public health and the environment.

- Only 52% of global sewage receives treatment, with developing countries treating just 4.2% compared to 74% in high-income nations • Sewage treatment involves four stages: preliminary screening, primary sedimentation, secondary biological treatment, and tertiary disinfection • Modern STPs use specialized equipment like bar screens, aeration tanks, and clarifiers to remove contaminants through physical, chemical, and biological processes • Treated wastewater becomes a valuable resource for irrigation, toilet flushing, industrial cooling, and even potable water with advanced treatment • Decentralized treatment systems cost 44% less than centralized plants while package STPs offer efficient solutions for residential and commercial properties

The hidden science behind sewage treatment demonstrates how engineering innovation transforms our most challenging waste streams into sustainable water resources, making these facilities essential guardians of both environmental health and water security.

FAQs

Q1. What is the basic principle behind sewage treatment plants?

Sewage treatment plants mimic and enhance natural water purification processes. They use a series of physical, biological, and chemical treatments to remove pollutants and contaminants from wastewater, transforming it into safe, reusable water.

Q2. How does a typical sewage treatment plant operate?

A typical sewage treatment plant operates through multiple stages. It begins with preliminary screening to remove large debris, followed by primary sedimentation to settle solids. Then, secondary biological treatment breaks down organic matter, and finally, tertiary treatment further purifies the water through filtration and disinfection.

Q3. What are the main components of a sewage treatment plant?

Key components include bar screens and grit chambers for initial filtration, aeration tanks for biological treatment, clarifiers for separating solids from liquids, and sludge digesters for processing solid waste. Advanced plants may also have tertiary treatment units for additional purification.

Q4. How is treated sewage water reused?

Treated sewage water has various applications. It’s commonly used for irrigation in agriculture and landscaping, toilet flushing in buildings, and as cooling water in industrial processes. With advanced treatment, it can even be purified to potable water standards for drinking.

Q5. What are the challenges facing sewage treatment globally?

A major challenge is the disparity in treatment capacity between developed and developing nations. While high-income countries treat about 74% of their sewage, developing countries manage only 4.2%. Additionally, even where infrastructure exists, there are often gaps in utilization, with some facilities operating below capacity.