In 2025, the demand for efficient, eco-friendly, and innovative sewage treatment plants (STPs) has reached an all-time high. With growing awareness about environmental sustainability, industries and residential communities are seeking cutting-edge technologies for effective wastewater management. This blog explores the best sewage treatment plants in 2025, placing SUSBIO ECOTREAT in the spotlight as the top choice, followed by other advanced treatment technologies like MBBR, MBR, SBR, and the Activated Sludge Process. all of which offer innovative solutions to enhance the sewage treatment process.

1. SUSBIO ECOTREAT

SUSBIO ECOTREAT leads the list as the most efficient, eco-friendly, and reliable sewage treatment solution available in 2025. Manufactured by SUSBIO, a pioneer in wastewater treatment, this advanced prefabricated sewage treatment plant is revolutionizing the industry with its cutting-edge design and innovative technology. SUSBIO ECOTREAT is not just a sewage treatment plant—it’s a complete solution for addressing wastewater challenges including well water treatment systems with a focus on sustainability, cost-effectiveness, and ease of use.

What Sets SUSBIO ECOTREAT Apart?

- Prefabricated Design: The plant comes fully prefabricated, ensuring quick installation and hassle-free transportation. This makes it a perfect solution for remote locations, urban areas, and industrial complexes.

- Eco-Friendly Technology: By employing biological and physical treatment methods, SUSBIO ECOTREAT ensures the treated water meets stringent environmental norms and is safe for reuse.

- Energy Efficiency: The plant operates on energy-saving mechanisms, reducing electricity consumption by up to 50% compared to traditional STPs.

- Durability and Longevity: Built with fiber-reinforced plastic (FRP) of the highest quality, SUSBIO ECOTREAT offers unmatched structural strength, capable of withstanding harsh environmental conditions. The material of construction comes with a 10-year warranty, ensuring peace of mind for clients.

- Scalability: It is designed to accommodate diverse client requirements, from small residential apartments to large-scale industrial projects.

- Cost-Effective Operations: Minimal maintenance, low operating costs, and reduced sludge generation make SUSBIO ECOTREAT a budget-friendly choice.

- Advanced Performance: It effectively treats wastewater with high Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD) levels, ensuring superior water quality.

SUSBIO ECOTREAT Process: A Step-by-Step Breakdown

SUSBIO ECOTREAT integrates advanced treatment technologies in a compact and modular system, making it highly efficient and user-friendly. Here’s how it works:

Primary Treatment (Physical Screening and Settling):

- Wastewater first enters the primary treatment chamber, where large solids, debris, and non-biodegradable materials are filtered out using fine screens.

- Heavier particles settle at the bottom, while lighter particles float to the surface, ensuring the wastewater is pretreated before moving to the biological treatment stage.

Biological Treatment (Dual-Stage Process):

- The first stage uses aerobic biological treatment, where oxygen is supplied to microorganisms that break down organic matter in the wastewater. This step is critical for reducing COD and BOD levels.

- The second stage involves a fixed biofilm process, where bacteria attached to specially designed media further digest organic matter. This ensures maximum efficiency in removing impurities.

Secondary Clarification (Sludge Separation):

- Treated water from the biological stage flows into a clarifier, where suspended solids and biomass settle to the bottom. The clarified water, now free of most impurities, is separated from the sludge.

Tertiary Treatment (Advanced Filtration):

- The water undergoes tertiary treatment using advanced filtration technologies such as sand filters or activated carbon filters. This step ensures the treated water meets the highest standards for reuse or safe disposal.

Disinfection:

- In the final stage, the water is disinfected using methods like UV treatment or chlorination, eliminating any remaining pathogens. The result is clean, odor-free water that can be reused for landscaping, irrigation, or other non-potable purposes.

Sludge Management:

- The sludge generated during the treatment process is collected in a separate chamber. It is treated and dewatered for safe disposal or used as fertilizer, making the system environmentally sustainable.

Why Choose SUSBIO ECOTREAT?

SUSBIO ECOTREAT is not just a product but a testament to SUSBIO’s commitment to innovation and excellence in sewage treatment. Here’s why it’s the best choice for 2025:

- In-House Installation and Service Team: SUSBIO ensures a seamless installation process and provides ongoing support for maintenance and troubleshooting.

- Compliance with Regulations: The plant meets all national and international wastewater treatment standards, making it a trusted solution for clients worldwide.

- Tailored Solutions: SUSBIO offers customized configurations to address the unique requirements of residential apartments, commercial complexes, and industrial facilities.

- Sustainability: By significantly reducing water pollution and promoting water reuse, SUSBIO ECOTREAT contributes to a greener planet.

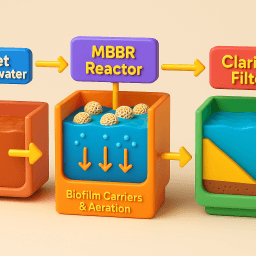

2. MBBR (Moving Bed Biofilm Reactor)

MBBR technology is a popular and reliable choice for wastewater treatment in various sectors. It uses biofilm-coated carriers within a reactor to break down organic matter in the wastewater.

Advantages of MBBR:

- Compact system requiring less space.

- High biological treatment efficiency.

- Easy to scale up for future requirements.

- Low sludge generation.

MBBR is widely used for industrial and municipal wastewater treatment due to its simplicity and efficiency.

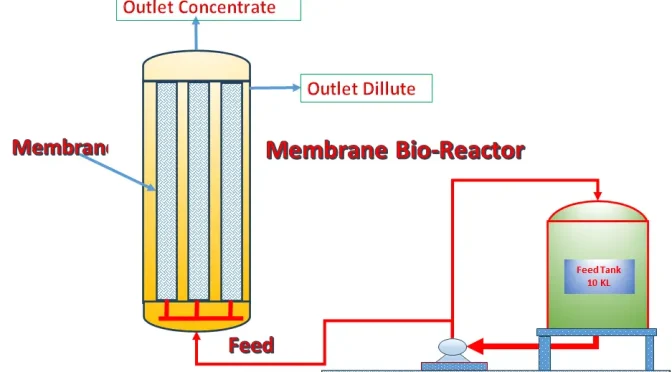

3. MBR (Membrane Bioreactor)

Membrane Bioreactor (MBR) technology has gained prominence for its ability to deliver high-quality treated water suitable for reuse in landscaping, irrigation, and other applications. It combines biological treatment with advanced membrane filtration.

Advantages of MBR:

- Produces high-quality treated water.

- Compact and modular design.

- Reduces suspended solids and pathogens effectively.

- Ideal for areas with stringent wastewater discharge norms.

However, MBR systems tend to have higher operational costs compared to other technologies, which limits their widespread application.

4. SBR (Sequencing Batch Reactor)

SBR technology is a time-based, batch process that effectively treats wastewater through aeration, sedimentation, and decantation phases. It is suitable for residential, commercial, and industrial projects.

Advantages of SBR:

- Flexible operation for varying loads.

- High-quality effluent suitable for reuse.

- Compact footprint.

SBRs are known for their versatility, making them a common choice for medium to large-scale projects.

5. Activated Sludge Process (ASP)

The Activated Sludge Process is one of the oldest and most widely used wastewater treatment methods. It uses aeration and a biological process to degrade organic matter in wastewater.

Advantages of ASP:

- Proven technology with a long history of success.

- Suitable for large-scale applications.

- Handles high organic loads effectively.

While it is reliable, ASP requires more space and energy, making it less efficient than modern technologies like SUSBIO ECOTREAT or MBBR.

Conclusion: Why SUSBIO ECOTREAT Leads the Pack

When it comes to sewage treatment plants in 2025, SUSBIO ECOTREAT is the ultimate choice. Its innovative design, energy efficiency, and adaptability make it a top-tier solution for residential, commercial, and industrial wastewater treatment needs. Compared to technologies like MBBR, MBR, SBR, and Activated Sludge, SUSBIO ECOTREAT stands out for its:

- Advanced prefabricated construction.

- Superior performance at high COD and BOD levels.

- Cost-effectiveness and low energy consumption.

- In-house service and technical support.

Whether you are looking for a packaged STP, a domestic sewage treatment plant, or a wastewater treatment solution for industrial projects, SUSBIO ECOTREAT ensures clean water, environmental compliance, and sustainability.

Choose SUSBIO ECOTREAT – The Best Sewage Treatment Plant in 2025!